GFHWoodWerks

Member

I would like to probe the hive for what lathe tools to try. There is a large variation of tools to consider so I'll ask the following questions, keep in mind we are talking carbide only.

1. Which tool length to get for pen and other small turning?

2. Standard or Negative rake? (Both is an acceptable answer as well)

3. Set or individual tools?

4. Brands worth looking at?

I would like to start by saying that I'm totally understand the buy once cry once mentality, but budget is a concern for most new turners because of all the upfront expenditure. So please take that into consideration when answering.

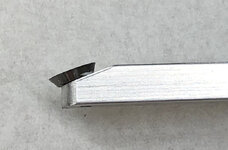

Bonus question: I saw this lathe tool in a YouTube video that had a shaped shaft (hexagon?). I can't seem to find it again, so it might not have value, but if you know what it is can you please edify me on what it is? Also if you've used it, I'd it worthwhile?

Thanks from a new turner, looking to save money through others experience.

1. Which tool length to get for pen and other small turning?

2. Standard or Negative rake? (Both is an acceptable answer as well)

3. Set or individual tools?

4. Brands worth looking at?

I would like to start by saying that I'm totally understand the buy once cry once mentality, but budget is a concern for most new turners because of all the upfront expenditure. So please take that into consideration when answering.

Bonus question: I saw this lathe tool in a YouTube video that had a shaped shaft (hexagon?). I can't seem to find it again, so it might not have value, but if you know what it is can you please edify me on what it is? Also if you've used it, I'd it worthwhile?

Thanks from a new turner, looking to save money through others experience.