MedWoodWorx

Member

when turning blanks between centers, a drive center is used; is that handmade? is there a drive center sold under a certain brand that is worth the cost or its irrelevant? thank you for any advice, cheers

www.chronos.ltd.uk

www.chronos.ltd.uk

The tail stock center is usually a "live" center in that, when mounted in the tail stock, it can be freely rotated by hand. Conversely, the center that goes into/mounts in the head stock is referred to as a "dead" center in that it rotates only as the head stock rotates - if you turn it, the head stock turns. CAUTION - don't try to turn the dead center by hand with the lathe running! The dead center is what makes you pen blank turn when the lathe is turned on. For tbc both the dead and live centers usually are 45 degree cones.thank you all for your advice, i can find mt2 drive centers in greece (i didn't know that tbc mandrels existed however); so it's the same part that is used as a tailstock center.

really? i thought 60 degrees.The tail stock center is usually a "live" center in that, when mounted in the tail stock, it can be freely rotated by hand. Conversely, the center that goes into/mounts in the head stock is referred to as a "dead" center in that it rotates only as the head stock rotates - if you turn it, the head stock turns. CAUTION - don't try to turn the dead center by hand with the lathe running! The dead center is what makes you pen blank turn when the lathe is turned on. For tbc both the dead and live centers usually are 45 degree cones.

DrD

Mike! They ARE 60 degrees. And sorry, I forgot you are in Greece. Where I had many good times when I was in the Navy.really? i thought 60 degrees.

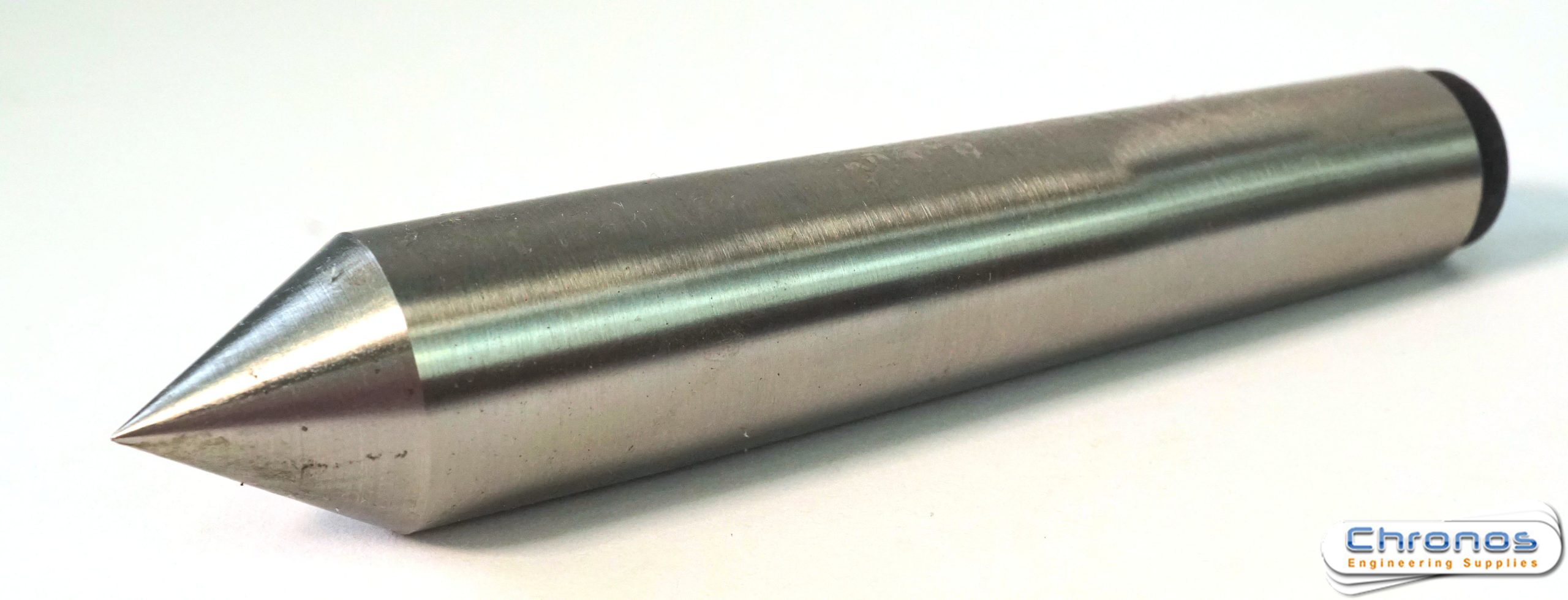

yes i see what you mean i am just clarifying what i read in this site : https://www.arceurotrade.co.uk/Catalogue/Centres/Morse-Taper-Dead-Centres

Morse Taper dead centres - hardened and ground.

Generally used in the tailstock for extra support when turning longer work or in the headstock and tailstock when turning between centres.