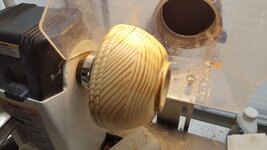

Skie, why would you ever put a 1" tenon on the bottom of your bowl blank? Have you ever checked out any bowl turning videos on You-Tube? If not, I'd suggest that you do, or talk to a bowl turner. All you need for a tenon is about 1/2", anything over that will usually bottom out on the chuck. All you want the tenon to do is to hold the blank level and square to the chuck. It can't do that properly, if it is bottomed out. Bottom line is, you never want your blank to bottom out in the chuck. And, you will never need a 1" tenon, on any bowl blank. I'm not surprised that the bowl blank went flying, with the tenon being so long. The blank was just floating in the air, it wasn't resting up against the face of the chuck jaws like it should.

Len