NewfoundlandLaw

Member

Hey All

Thought I'd share my other pass time.

For the past 2 years I've been trying to perfect my knife making skills. While I am still very much an amateur, I enjoy the challenge of freehand grinding knives.

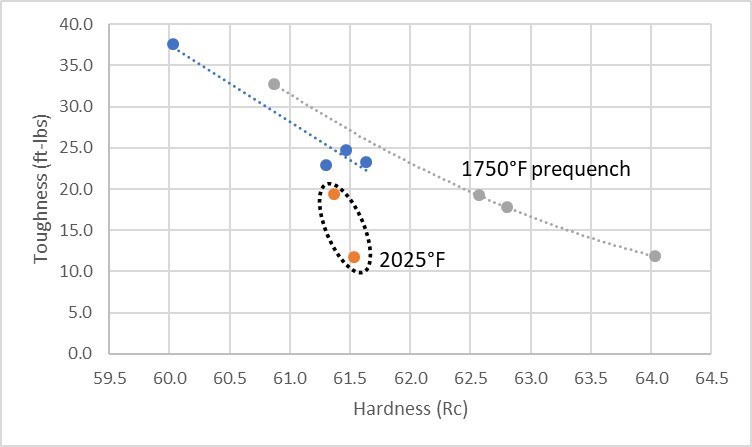

I also love the science that goes into hardening and tempering newer high-end steels. It involves everything from digitally controlled steels to Liquid Nitrogen submersion.

I've even gone as far as to invest in a proper high-end Rockwell tester.

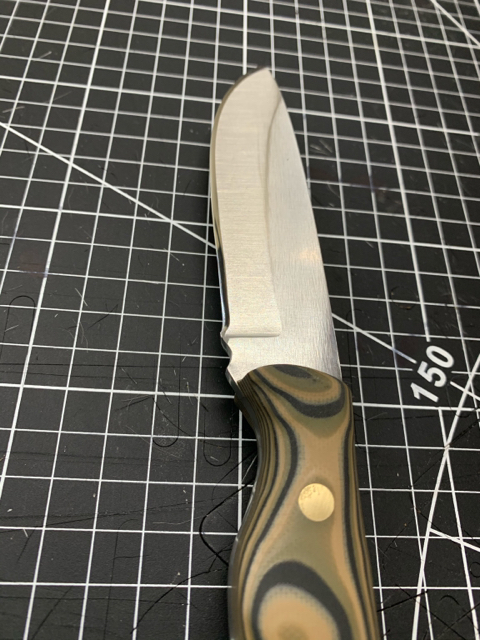

Here are some examples of my work:

"Pen Turning on the Rock"

Thought I'd share my other pass time.

For the past 2 years I've been trying to perfect my knife making skills. While I am still very much an amateur, I enjoy the challenge of freehand grinding knives.

I also love the science that goes into hardening and tempering newer high-end steels. It involves everything from digitally controlled steels to Liquid Nitrogen submersion.

I've even gone as far as to invest in a proper high-end Rockwell tester.

Here are some examples of my work:

"Pen Turning on the Rock"