Ok I just got a new 4 jaw chuck with extra jaws from PSI.

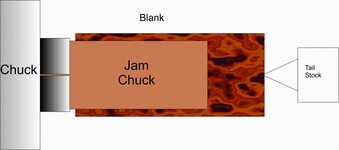

I'm thinking of making this style pepper mill and thinking I could use my new chuck instead of the rubber jam chuck.

https://www.pennstateind.com/library/PKGRIND10_INS.pdf

Trying to figure out if I'm missing any tricks to using this chuck to make this mill. I would still drill out the blank with the forstner bit but just not sure if I could grab it correctly and turn some of those parts so thin using the jaws.

Maybe I could make a really big pin chuck and use that.

I'm thinking of making this style pepper mill and thinking I could use my new chuck instead of the rubber jam chuck.

https://www.pennstateind.com/library/PKGRIND10_INS.pdf

Trying to figure out if I'm missing any tricks to using this chuck to make this mill. I would still drill out the blank with the forstner bit but just not sure if I could grab it correctly and turn some of those parts so thin using the jaws.

Maybe I could make a really big pin chuck and use that.