I have the one TWVAMAN sent me. Pm your email address and I can send that file. I haven't created anything custom

Related to certificates for bog oak pen blanks:

I sent the PM and @RVA_Tyndall was kind enough to send me a copy of his file, which is the same one that I got from the seller. I didn't realize that the last page was intended as a certificate. It has a "watermark" image of green tree rings in the background. It looks like someone copied the texture of the paper, too. Here is the text from the certificate:

"Dendrochronological Dating Certificate

from the Dendrochronological

Laboratory

Queens University Belfast

"Site Name: Derrycanan Bog, Co. Roscommon

Laboratory ldentification: Q11944

Date of Measurement: 13th March 2017

Number of Measured Rings: 168

Submitted by: Michael Hanley

"Dendrochronological Date:

The Measured Tree-Ring Series Dates from 4663BC to 4496BC

The Estimated Death Date for the Tree will be 4464BC +/- 9 years or later

"David Brown

School of Natural and Built Environment

Queens University Belfast

Belfast

BT7 lNN"

With no disrespect intended, a botanist might appreciate that certificate, but not my spouse's 85 year old aunt of Irish heritage, who is the intended recipient of my first bog oak pen.

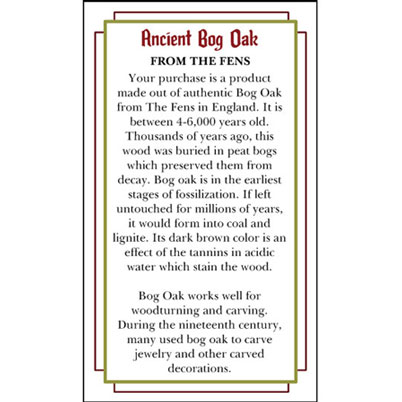

I had hoped for a small card, like the ones that come with Bethlehem olive wood. The card would give a simple description, not technical, and have an artistic, decorative border. Maybe a few graphic icons of Irish symbols. Something tasteful; definitely not images from the Lucky Charms cereal box. :-(

I found several images from web searches. Here is an example for bog oak wood from England. It could serve as a template to make your own for Irish bog oak:

After finding a few online images, I think I have enough ideas to make my own cards for my pens. If I come up with something really good, I'll post it here. Otherwise, start with a web search and good luck!

Special thanks to RVA_Tyndall for sending me the file!

P.S. You can find Derrycanan Bog on the map:

https://www.google.com/maps/place/Derrycanan+Bog,+Co.+Roscommon,+Ireland/

If you zoom in from the satellite view, you can see how they are harvesting the bog oak around the perimeter, near the roads and other access points.