ekeogh

Member

Hi All

I hope someone is out there that can help me as I am a beginning turner.

I have turned several pens on both wood and acrylic and I want to finish them in CA finish

Although I know this takes practice and I have watched several YouTube videos my question is

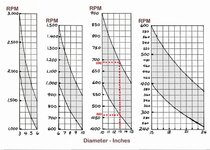

I have a Rockler Excelsior midi lathe and the lowest RPM is 720 but almost everywhere I am looking every one is recommending 200 RPM ???

What do I do?

I hope someone is out there that can help me as I am a beginning turner.

I have turned several pens on both wood and acrylic and I want to finish them in CA finish

Although I know this takes practice and I have watched several YouTube videos my question is

I have a Rockler Excelsior midi lathe and the lowest RPM is 720 but almost everywhere I am looking every one is recommending 200 RPM ???

What do I do?