Carl Fisher

Member

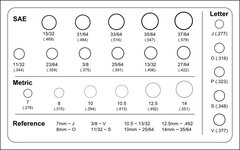

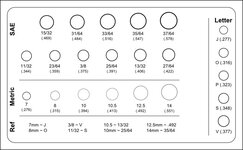

Playing around with a layout for a drill bit holder designed specifically for pen maker sized bits.

I went through all of the tube/drill size spreadsheets and I think I pulled all of the bit sizes for all of the kits with maybe one or two exceptions for the obscenely large real cigar holder and something else which I forget.

What other information would you like to see in the quick reference section besides cross reference of approximately compatible bits?

I'll be cutting these on my CNC from wood. Each hole is .01 for SAE and .1 for metric oversized to allow easy insert/removal. I'll have to play with that a bit once I cut some prototypes to make sure that's enough clearance.

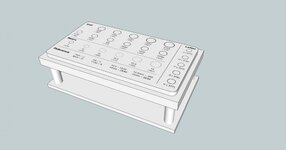

I haven't drawn up a 3D version yet, but I figure the upper deck to be either 1/2" or 3/4" material with through holes for the bits and some 1/2" standoffs underneath with a lower platform for the stop.

Depending on the wood I end up using and figuring out the best way to color in the engravings, I'm targeting around a $20-25 price point. So I guess the question is would there be interest and what changes would you like to see?

I went through all of the tube/drill size spreadsheets and I think I pulled all of the bit sizes for all of the kits with maybe one or two exceptions for the obscenely large real cigar holder and something else which I forget.

What other information would you like to see in the quick reference section besides cross reference of approximately compatible bits?

I'll be cutting these on my CNC from wood. Each hole is .01 for SAE and .1 for metric oversized to allow easy insert/removal. I'll have to play with that a bit once I cut some prototypes to make sure that's enough clearance.

I haven't drawn up a 3D version yet, but I figure the upper deck to be either 1/2" or 3/4" material with through holes for the bits and some 1/2" standoffs underneath with a lower platform for the stop.

Depending on the wood I end up using and figuring out the best way to color in the engravings, I'm targeting around a $20-25 price point. So I guess the question is would there be interest and what changes would you like to see?

Attachments

Last edited: