Displaced Canadian

Member

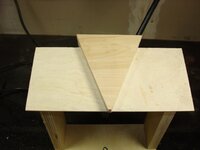

Here are some pictures of the jigs that I have made to sharpen turning chisels. The WS isn't fastened down so it can be moved around to use all the sandpaper. I use loctite spray adhesive #100 and buy my sandpaper at the local hardware store. The bases are just large enough for the sharpener. It is important to build in some kind of brace so the jig doesn't rock when sharpening. The gouge does catch a little when you start to turn into it, not sure what the best way to solve that is and I just live with it. If possible I would make the tops a little longer on the short ones so you have more space for the clamp to hold the guide down. I used 3/4" plywood because I had it on hand. I think thicker wood the better to help with stability. If you have any questions or ways to make these better please say so. Thank you.