Bob Wemm

Member

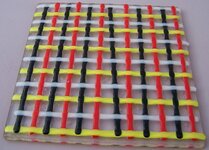

I've had a lot of fun with this, only 5 failed attempts to get the glass bent correctly.:redface:

The Trivet is 6in square and the four colours woven and then fused to clear glass.

This is a VERY FIRST for me, but has been done by others many times.

The last photo is the underside, just to prove that it has been woven.

Hope you like it, and thanks for looking.

C&C welcome as usual.

Bob.

The Trivet is 6in square and the four colours woven and then fused to clear glass.

This is a VERY FIRST for me, but has been done by others many times.

The last photo is the underside, just to prove that it has been woven.

Hope you like it, and thanks for looking.

C&C welcome as usual.

Bob.