alxe24

Member

Wooden Eggs

The eggs are roughly 1â€5/8 by 2â€3/8 which is about life size depending on the egg. The one dimension that is important to keep about the same on all eggs is the diameter since this is how the egg is grabbed later to turn the ends and the ID of the chuck I made is 1â€5/8. It gives some latitude either way but not a whole lot, so diameter is important.

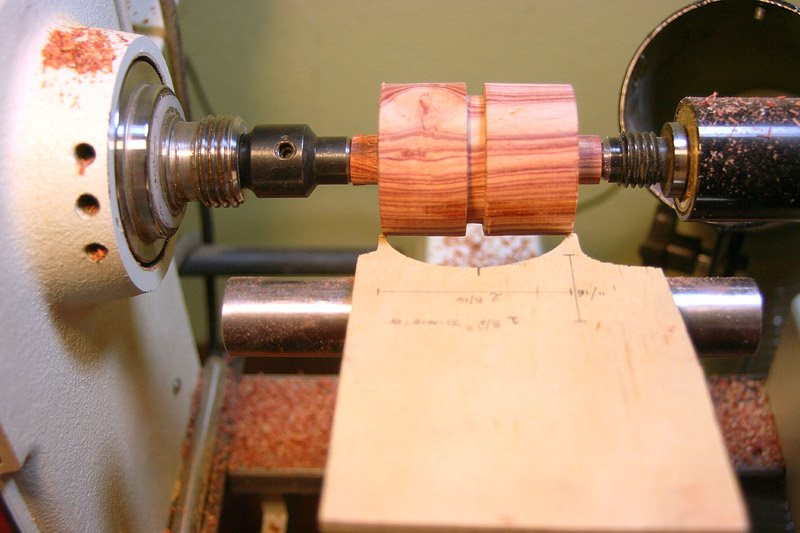

The first thing is cut a blank to fit the size of the project and turn round between centers.

Once this is done mark a line on the widest part of the egg and both ends. With a parting tool turn the center line close to the final diameter and turn down the waste at the ends. It is a lot easier to make a few templates with the contour of the egg. This will save a lot of time getting to the right shape. I suggest 4 templates one for each end and two for the center, one with a partial part on the center top and the other one close to the full shape but not all the way since the ends are still thicker.

Once happy with the looks sand and finish the egg, make sure not to part off the ends since the ends are going to aid to get the egg to run true when mounted on the chuck.

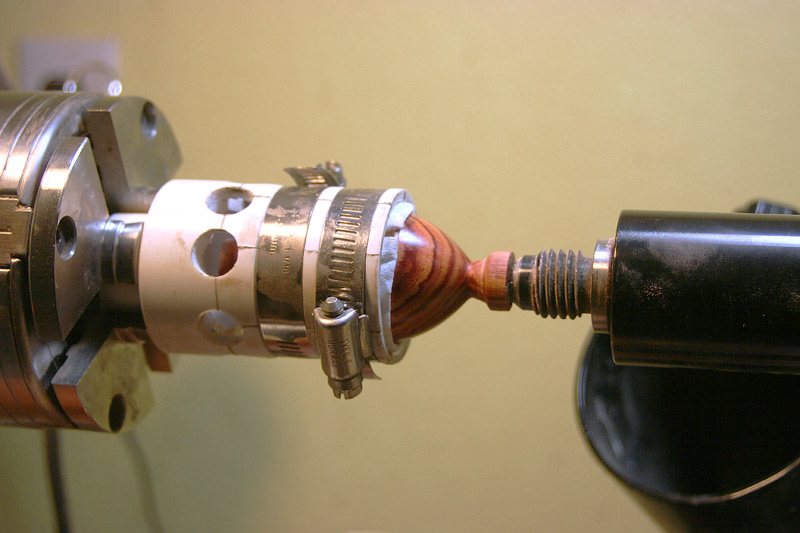

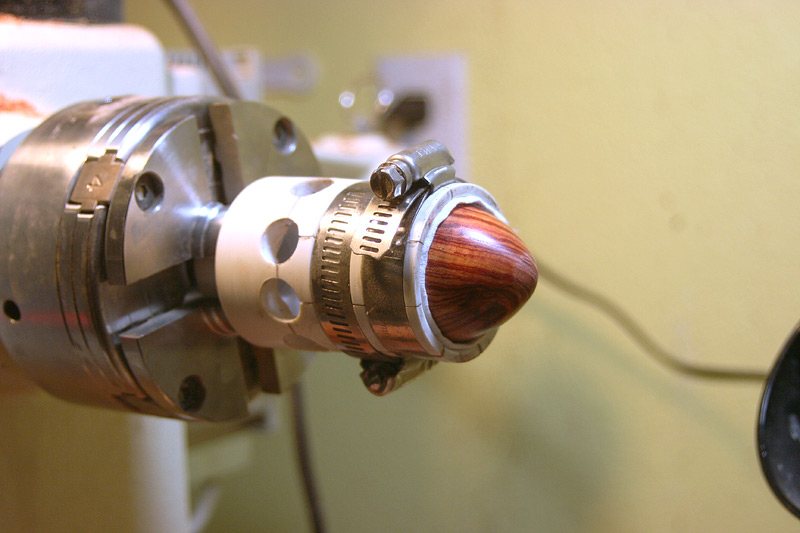

Mount the chuck and put the egg inside, if the fit is a bit loose put some paper towel around the egg. Bring the tail stock and position the point on the dimple, lock the tail stock bring the end of the egg tight against the live center and then tighten the hose clamps. Make sure they end runs true and turn the first end to shape. (MAKE SURE THE HOSE CLAMPS CLEAR THE TOOL REST AND KEEP YOUR HANDS FAR FROM THEM. THOSE CLAMPS ARE FEARLESS OF YOUR FLESH. I SPEAK BY EXPERIENCE)

Once one end is finish sand and finish it, turn the egg around and repeat the process on the other end.

And then after the efforts comes the rewards. This will be buffed in a few days to bring a nice shine to it. One more for the collection.

The eggs are roughly 1â€5/8 by 2â€3/8 which is about life size depending on the egg. The one dimension that is important to keep about the same on all eggs is the diameter since this is how the egg is grabbed later to turn the ends and the ID of the chuck I made is 1â€5/8. It gives some latitude either way but not a whole lot, so diameter is important.

The first thing is cut a blank to fit the size of the project and turn round between centers.

Once this is done mark a line on the widest part of the egg and both ends. With a parting tool turn the center line close to the final diameter and turn down the waste at the ends. It is a lot easier to make a few templates with the contour of the egg. This will save a lot of time getting to the right shape. I suggest 4 templates one for each end and two for the center, one with a partial part on the center top and the other one close to the full shape but not all the way since the ends are still thicker.

Once happy with the looks sand and finish the egg, make sure not to part off the ends since the ends are going to aid to get the egg to run true when mounted on the chuck.

Mount the chuck and put the egg inside, if the fit is a bit loose put some paper towel around the egg. Bring the tail stock and position the point on the dimple, lock the tail stock bring the end of the egg tight against the live center and then tighten the hose clamps. Make sure they end runs true and turn the first end to shape. (MAKE SURE THE HOSE CLAMPS CLEAR THE TOOL REST AND KEEP YOUR HANDS FAR FROM THEM. THOSE CLAMPS ARE FEARLESS OF YOUR FLESH. I SPEAK BY EXPERIENCE)

Once one end is finish sand and finish it, turn the egg around and repeat the process on the other end.

And then after the efforts comes the rewards. This will be buffed in a few days to bring a nice shine to it. One more for the collection.