jttheclockman

Member

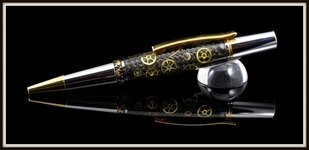

OK it has been long enough and there are many people who make the watch part blanks. There are many videos of these things too so the mystery is out of the bag.

But with that said I would like to try my hand at some of these. I have gathered the parts dials and have all tools including dabbler blocks pliers and what ever else. I have that covered. Now I do have a few questions and remember we are a sharing group so please do not tell me it is a trade secret.

Here is my questions. What is everyone using to glue the parts to the tubes and is one thing better than another?? I have heard nail polish, CA glue, med, epoxy. When using any or all of these how important is it to not get glue beyond the parts?? Will the glue show when cast?? Next question what resin is everyone using to cast these. I was thinking Liquid Diamonds epoxy resin. I also have Silmar. Next question, is there any other tidbits of info that you can share to make this go smooth. I see right away I will have to break out the magnifying light for sure.

I have watched Chad Schimmels videos and yes they are well done but are there any others worth while taking a look at to get a better feel for this project??

Thanks all for the replys.

But with that said I would like to try my hand at some of these. I have gathered the parts dials and have all tools including dabbler blocks pliers and what ever else. I have that covered. Now I do have a few questions and remember we are a sharing group so please do not tell me it is a trade secret.

Here is my questions. What is everyone using to glue the parts to the tubes and is one thing better than another?? I have heard nail polish, CA glue, med, epoxy. When using any or all of these how important is it to not get glue beyond the parts?? Will the glue show when cast?? Next question what resin is everyone using to cast these. I was thinking Liquid Diamonds epoxy resin. I also have Silmar. Next question, is there any other tidbits of info that you can share to make this go smooth. I see right away I will have to break out the magnifying light for sure.

I have watched Chad Schimmels videos and yes they are well done but are there any others worth while taking a look at to get a better feel for this project??

Thanks all for the replys.