Thank you all for contributing to this thread,

There seems to be a big difference between the various speeds used by the Turners at IAP, and of course it must all come down to personal preference and at what speed you feel comfortable at your lathe with the tools you have available.

What is surprising to me as a relative newcomer is the fact that some turn at twice the speed of others and all produce an excellent pen at the end of it!

So, I suppose it is "what works for me"

Mike

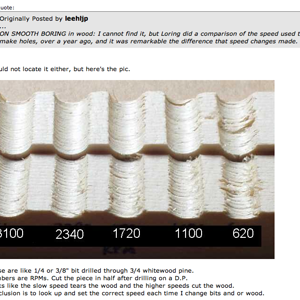

Mike, the OP is intended to focus on a misconception by more than a few - concerning turning speed. I have been on this forum for 16 years now and read posts regularly. It is not "just a matter of preference" per se - because consistently going back these 16 years, many slow speed users were taught to "never turn more than 1000 rpm" and these turners in particular are the ones that have problems with acrylic and cast blanks. Some questions are from those who are just starting, but an equal amount is from experienced bowl turners. In the past few months, I have or others have replied to queries concerning "how to turn . . . acrylic/cast blank" constantly - because they were having difficulty.

After a few answers then someone, or me in a couple of cases, would ask: "What speed are you turning?" Answer: "1000 rpm."

Well, that was the problem. Their next reply was: I went to . . . for turning lessons and they said never turn more than 1000 RPM. (But the instructor meant that answer for turning bowls." Early on here on this forum, there were discussions in which several from the bowl turning community made comments that pen turners were turning too high - and that was what they were used to for many years. To keep this honest, there were bowl turners here who made excellent pens, but they also were perceptive, observant and intuitive and knew that smaller diameters required faster speed.

Yes, it is up to the individual, but there is also the reality that bowl turning rpm doesn't work as well as pen turning rpm for pen blanks. This was the purpose of this thread. And another honesty, the pen turning jig that was used over a flat bottom router bit in a router table "can work", it will cause problems with quality down the road. So does slow bowl turning speeds. That has been a problem for some here since the beginning. Yes, people can choose their own speed, and slower rpm speed does have more problems when it comes specifically to cast blanks, and in some cases with wood blanks.

I ran into this with a wood pen about 12 - 13 years ago. I made a segmented pen that I learned real quick could not be sanded. I did all kinds of things and it was a combination of two things that made it smooth without the need for sanding on the wood: speed 3000+rpm and razor sharp. No other way to produce that. I have run into a few bowl turners with knowledge and experience and they have made bowls smooth without sanding. Two things for them: Fastest safe speed possible for that diameter bowl and extra sharp tools.