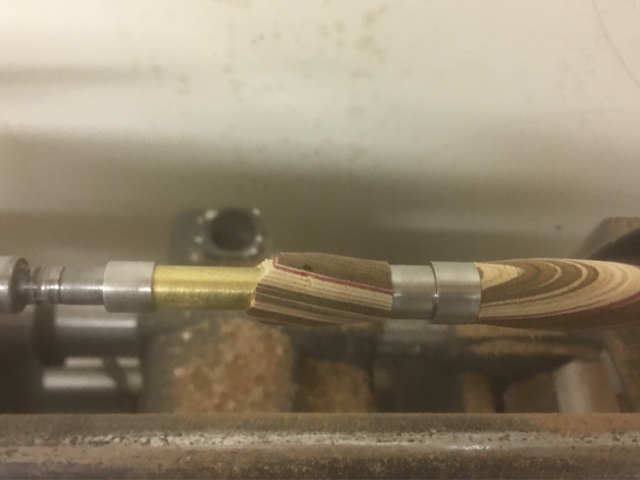

Second attempt at turning spectraply. Both times ended with the same result. Looking for some advice.

Sent from my iPhone using Penturners.org mobile app

Sent from my iPhone using Penturners.org mobile app

It looks like it might be a glue up problem.

Do you use epoxy or CA?

Mike