I've been working on my turning problems with pens. I think a lot of my sanding problems come from the vibrations I experience while the blank is spinning, and as I'm trying to clean up the ends of my blank with sandpaper, I end up just ruining them. But, I think it all stems from vibrations, notably at the live center end of things.

I've been trying a lot of the things you guys have been sharing (from this thread, and another about out of roundness/non-concentricity), and also found a PDF file from these forums that explained a TBC technique. I followed most of the instructions in that PDF, which starts with turning the blank round, then down to just a bit above the bushings, with whatever system you prefer. Once you have mostly turned down the blank, you ditch the mandrels and bushings altogether, and just put the brass tube with the blank between two centers. No bushings, just the tube and the blank.

From there, you re-true the blank. If you have vibration problems like I do, this is necessary. I think, now that I've been digging into this problem for a couple weeks now, is due to several issues with...all of my mandrels and centers. Once I've have the blank trued up, and at this point for me this is the first time I'll hear the tool cut the wood cleanly without many vibrations or continual chatter or anything like that, then I can turn it down to the appropriate size by measuring with calipers. This is slower for sure, takes a lot of checking, and you have to take really fine, light cuts as the thinner the blank gets over the brass tube, the harder it is to avoid ripping it to pieces. There is still a small amount of vibration at the live center end...but, more on this in a moment.

If I am extremely careful, once I'm turning sans bushings and just between centers, I can get the blank turned pretty accurately. In some cases, with some kits, I was able to turn a bit smaller than the bushings, as the bushings weren't really sized right...the bands on two kits I turned recently have convex aspects to them, and when turning just down to the bushings, the blanks have a hard right-angle edge that butts up against these convex shapes, and it doesn't look good. On the second of these two kits, I did this sans-bushing TBC turning, and turned the blank down to about ~0.445", while the bushings were ~0.46". The second kit looks better. The wood ended up quite thin doing this, however, so its very very delicate work! I have picked up some Mercury Flex CA to try CA finishing again...I have always been worried that adding CA will expand the diameter of the pen (well, at least in my experience, it does, making the blank thicker than the bushings). I think with sans-bushing turning, I will be able to thin the blank out a bit more, giving me room to build up some layers of CA without that worry...hopefully.

----------

I have a

lot more practicing to do, but this

may be what solves most of my pen turning problems in the long run. I believe

ALL of my centers have problems that are leading to my issues. So I'll also have to resolve that. I have the PSI TBC system, a PSI fixed shaft mandrel, and a normal pen turning mandrel from my original slimline starter kit, as well as some standard live centers, including a very common 60 degree live center:

WoodRiver 60 degree cone live centers are perfect for pen turning mandrels weed pots or general turning projects These heavy duty ball bearing centers can also be used for hol

www.woodcraft.com

The vibrations prevent me from turning the blank down to the proper dimensions. As a little test, I can put my fingernail up against a bushing while it is spinning. If my fingernail touches without any ability to "see through" the bushing and my fingernail, then the bushing is likely turning true. This is usually the case with the bushing at the headstock end. When a bushing is vibrating, my fingernail cannot actually be fully pressed into the bushing, and there will be (at high speed) what looks like an air gap between the bushing and my fingernail. The thickness of that gap, is usually the amount of non-concentricity or out of round that I'll end up with on the blank at that end. I've tried flipping the blank around, but, once I've turned it down enough to identify the problem, flipping it around usually means the non-concentricity remains, and if I turn the edge that is higher than the bushing down, the other edge ends up smaller than the bushing...so non-concentricity, once it is there, doesn't seem correctable unless you get rid of the bushings and just put the blank directly between centers (which is then a much more meticulous process.)

First, both my pen mandrels have bent shafts! Including a rather expensive one from PSI. The PSI one is actually worse than the classic kurled brass nut type with the adjustable shaft. The PSI one has become rather useless, as the vibrations are completely untenable. I bought that a while back, months ago, so I may not be able to return it...although when that didn't actually fix any problems when I first bought it, I stopped using it as I ordered the PSI TBC mandrel system. So its hardly had any use, mostly still looks like new, and is still in its original red container. Anyway...

The TBC mandrel also has problems. It seems like it has a slightly bent shaft on the live center part, but I don't think it is actually bent, or if it is, its not all that much, or maybe just circumstantial. The dead and live center both have about a 1" shaft on them, or "pin" I think its properly called. Anyway, I was experimenting with that earlier, and I found that the bearing is very "soft"...its not a tight fit, and just a bit of twisting the live center with relatively mild force with my fingers can twist it a bit, and the pin will move around (change angle). I think depending on exactly how the bushing seats onto the live center, it will shift the angle of the live center on the bearing, and then the pin would effectively be wobbling once the lathe is turned on. I've had plenty of vibration problems with this, and I believe those can all be traced back to this "soft" bearing. I tried to tighten that up, but I don't have any tools that seem sufficient to allow me to try and tighten the plate that covers the bearing...so, this tool may also be useless.

(I've tried contacting PSI several times about this through their contact form, but over the last week and a half I've received no reply. I'll be tryin to give them a call next week, to see if I can get these items replaced...but, ATM, I'm extremely dismayed at the quality of these tools. They came right out of the box with these problems!)

I also found issues with my 60 degree live center...it is not actually truly tight in the bearing either, it is soft like the PSI TBC mandrel. It also seems to settle into a position where when I bring the tailstock up so I can have my 60 degree dead and live center points almost touching, then rotate the live center, I can tell that it does not in fact spin entirely true! The tip of the live center wobbles slightly around the tip of the dead center. At speed, this wobble is about the magnitude of the vibrations I've experienced with bushings between these two centers, and about the size of the non-concentric shift to one side I end up having with blanks I turn that way (maybe, half to two thirds of a millimeter.)

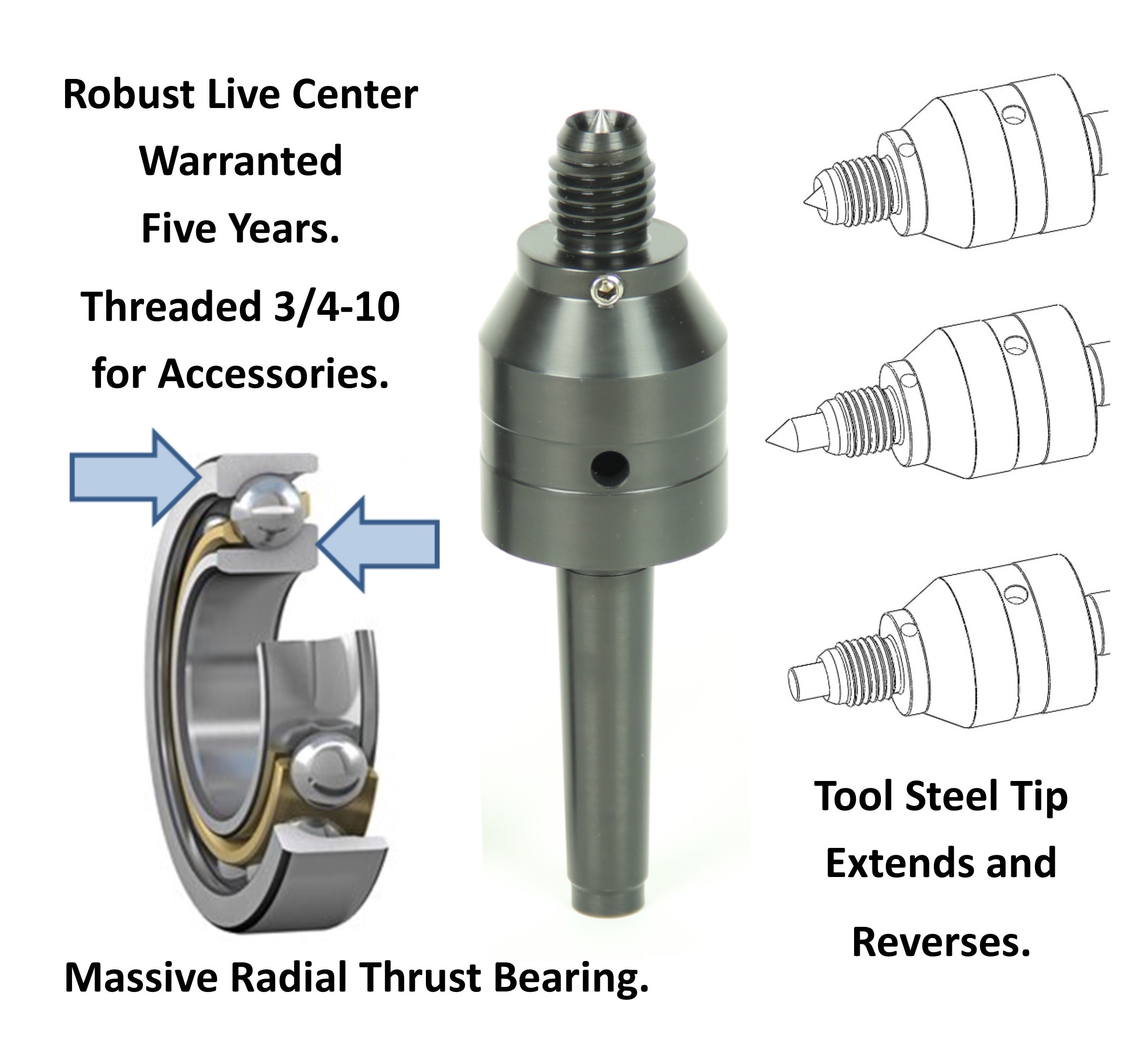

This is one of those very common live centers, the type I linked above, I see almost every turner I watch on YouTube using one of these, except those that use the Robust/OneWay/EWT type modular live centers (which are a lot more expensive.)

Oh, I also have two different kinds of "Mandrel Saver" type live centers. One I picked up at the local Woodcraft, I think it was around $30 or so, and the other I bought from Craft Supplies USA. Both also have soft bearings, where you can wiggle the live center on the bearings. The "Apprentice Live Center" I picked up from Craft Supplies has a VERY loose bearing! It only stabilizes once its got quite a lot of pressure on it...a lot more pressure than I'm comfortable putting on a pen blank and brass tube. That one I may still be able to return, I'll have to see.

So it seems every tool I have to turn pens, has an issue that causes vibration. All told, the cost of all of these tools is something like $180 or so. I find that rather depressing, that so many tools all have manufacturing issues like that. I'm not entirely sure what to do, either... If anyone has any highly reliable options they could recommend, I'm all ears. Even with just pure TBC without bushings or anything, my 60 degree live center still has its wobbling problem, and without any bushings you cannot put much pressure on the tube, otherwise you risk expanding it and preventing tight compression fit for the pen parts, or even cracking the blank. So the live center still causes a slight bit of wobble at the far oh, 1/3rd of the blank. Less than when using bushings, but...its still not ideal.

I have also experimented with the tailstock on my wen. I've tried locking it down in different ways...pushing it back in the track, pulling it forward, angling it left or right. The difference each of these adjustments make is minuscule, barely detectable. I've also tested bringing the live and dead center points together with the quill retracted and fully extended, and in both positions the points seem to come to the same place (the 60 degree live center obviously has its wobble problem, but I'm not noticing that there is actually a difference in the position it comes to when I bring the points together.) I'm checking the point locations both from the side and the top, and they are darn close to each other. The Laguna is currently out of commission awaiting a motor repair, so I haven't tested anything on that yet.

Anyway...the few couple of days (well, in total probably a couple of weeks) have been very revealing, and extremely disappointing! I'm amazed at how poor quality most of these tools are. Just floored. I now understand why I've had so man problems...but, I'm at a loss as to what to replace all of these with. Its a huge waste of money for the most part...I may only be able to return one or two of these items. What a journey. At least I understand the core of the problem, though...so hopefully I can find the right tools from the right brands, and put these issues behind me.