Our Home Depot has the sticky backed circular sandpaper. I've also just cut out a circle and used 3M spray adhesive to attach it to my disc. I agree one can move the paper around, but the jig is SO nice and I don't regret the purchase (JMHO)

Regards,

Michael

I can move the paper 10 times faster than you move that jig:biggrin::biggrin::biggrin:

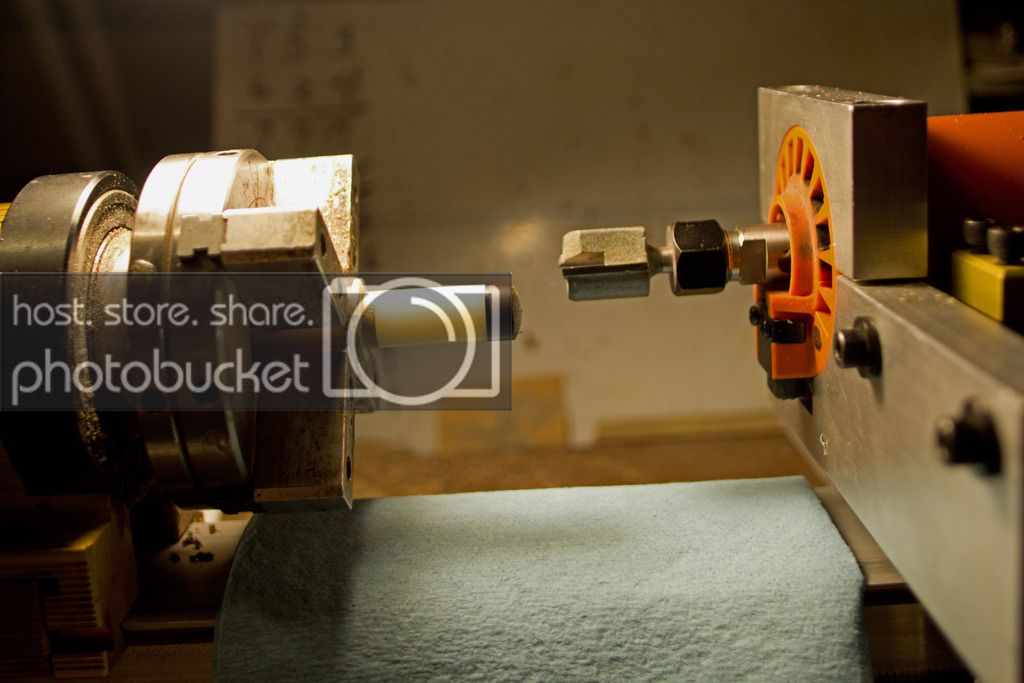

I here ya'! You must have a better solution to moving the paper than I did. I'd stick it, it would come off, I'd re-stick it and square a couple of blanks, then repeat with another piece. The jig is so easy--I'd guesstimate under 10 seconds to re-position it. I did add a couple more allen bolts (and my ONLY complaint is that it only comes with one so I had to spend another dollar and a half at the hardware store) so a quick loosen with the allen wrench, move the jig to the next position and re-tighten.

I love the fact that you can use the outside area of a 5" sanding disc--takes off material much more quickly than just using the center.

That's what's great about this process--many different solutions.

Regards,

Michael