ccccchunt

Member

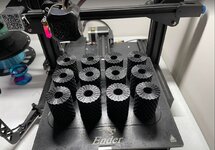

Been thinking about the honeycomb bottle stopper discussions and how most people stay away because you always have one axis that looks a bit strange. I have solved that for the most part with my 2" vertical pours. This is the next step. I had a guy do up a 3d design that has the honeycomb array always going to the outside. Should make for an interesting blank. My plan is to affix a honeycomb slab on the top also so the pattern should be the same pretty much 360 degrees.