longbeard

Member

Scott, when you say "slice it in half", do you mean slice it from top to botom in half or as it sits in the pic, from side to side?

Harry

Harry

Scott, when you say "slice it in half", do you mean slice it from top to botom in half or as it sits in the pic, from side to side?

Harry

Scott, when you say "slice it in half", do you mean slice it from top to botom in half or as it sits in the pic, from side to side?

Harry

Down through the pith(preferably getting rid of it at the same time:wink...no sense in making 'cookies' out of it!

Scott (I got a big saw) B

Scott (yes, I'll photo some stuff) B

Scott (yes, I'll photo some stuff) B

Ha ha, was about to say that!

Outstanding! But 35% humidity is not considered humidity Scott...:biggrin:

Outstanding! But 35% humidity is not considered humidity Scott...:biggrin:

I wish...this morning it was thick enough to cut with a knife. Just before I started cutting, I looked at WunderGround App thing, it was showing 77%. I'm sure as the temperature went up and the air was able to hold more moisture the humidity lowered....a LOT! But then it was just hot....

Scott (I was making humidity too....sweat) B

Scott, is that some kind of ivy growing up the side of the cherry trunk?

I haven't lived in America long enough to recognize the difference between what my wife calls "poison ivy" and the stuff that's benign ... hope that what I see there is not the type they make into a Batman villainess

Drag it all over here. We are at 8% humidity and 94. I have a shop big enough to handle it, a swamp cooler, and an empty studio apartment you can use. Just don't say anything about the slabs that seem to just disappear.:biggrin:

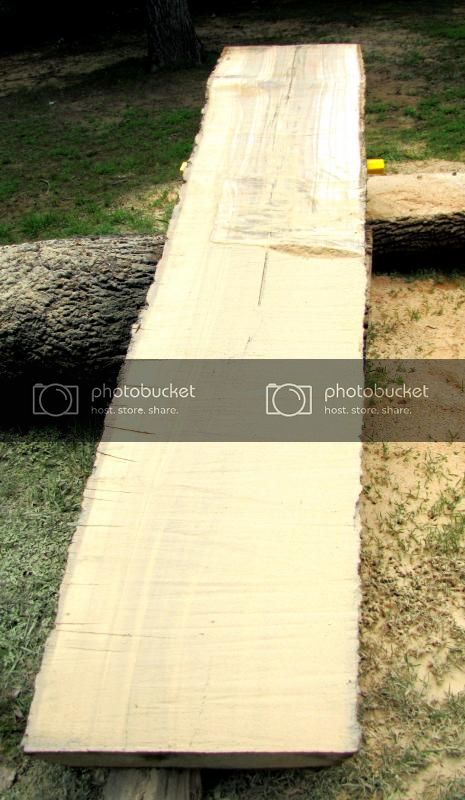

Getting tired of seeing this yet?

Getting tired of seeing this yet?

Bring 'em on!!

Man that cedar looks amazing. Bet it smelled nice while milling that.

didn't know it was an irritant. Thanks. I've turned a couple of small items but with the DC on. I can imagine it could be really problematic for you and the mill.

Thanks Warren!

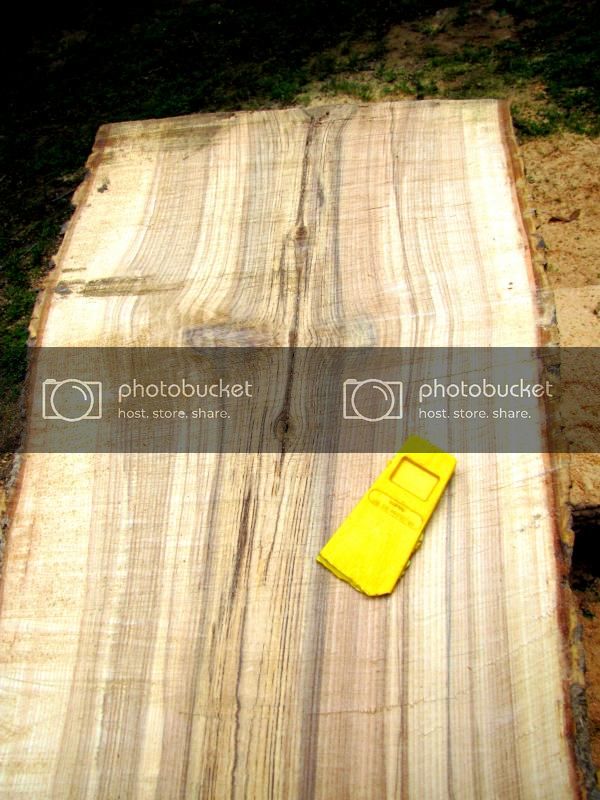

BTW, here is a piece of sweetness from the mill today!

This is a bowl blank I made from the Oak burl(technically, it was a Southern Red Oak)! Guess sooner or later I'll get it put on the website.....maybe, maybe not? I'm thinking this would make a really nice bowl for my craft table.........

Scott (and I mowed the lawn too) B