Rtibbs

Member

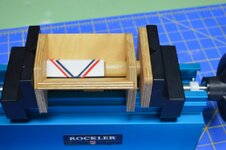

I modified the Rockler drill jig to use as a press when gluing pen segments by adding a carriage to the framework. As soon as I find my sheet of sticky back Teflon I'll line the carriage with it to prevent the glue from sticking to it.

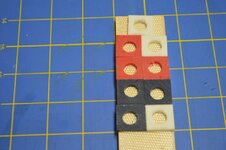

After cutting the segments I adhere them (Double faced tape) to a carrier and run them through my Byrnes thickness sander to smooth the surface then flip them over and run them through again. One of the nice things about the sander you can run two 3" wide sanding drums on the unit. One coarse and one fine grit side by side or one 6" wide drum with one grit.

After cutting the segments I adhere them (Double faced tape) to a carrier and run them through my Byrnes thickness sander to smooth the surface then flip them over and run them through again. One of the nice things about the sander you can run two 3" wide sanding drums on the unit. One coarse and one fine grit side by side or one 6" wide drum with one grit.