dscott

Member

any plans on making a jig to use on a sanding disk to square blanks

Originally posted by dscott

<br />any plans on making a jig to use on a sanding disk to square blanks

Originally posted by dscott

<br />any plans on making a jig to use on a sanding disk to square blanks

Originally posted by its_virgil

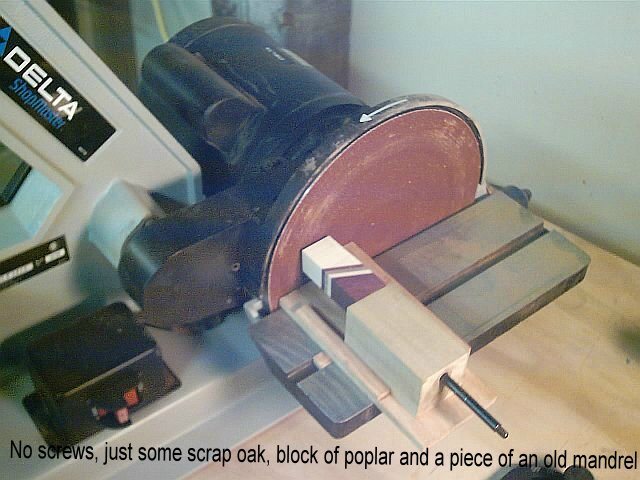

<br />Here's another picture.

<br /> Originally posted by dscott

Originally posted by dscott

<br />any plans on making a jig to use on a sanding disk to square blanks