Hello,

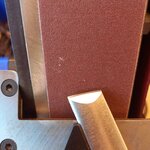

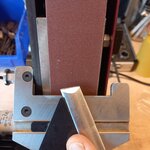

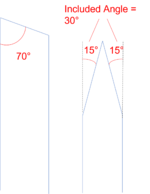

I bought a sorby pro edge and a skew jig to go with it. Now I hold my Hamlet skew on the sorby and the angle is way off. It's so much off it makes me doubt what to do. Grind it down or send the jig back and do it from hand.

I could use some advice on this one.

I bought a sorby pro edge and a skew jig to go with it. Now I hold my Hamlet skew on the sorby and the angle is way off. It's so much off it makes me doubt what to do. Grind it down or send the jig back and do it from hand.

I could use some advice on this one.