Hello,

I'm debating between some Proxxon equipment and Byrne's model machines (or maybe something else?). Hope any of you with experience can help!

I plan to do mainly segmenting and other complex small work of that kind.

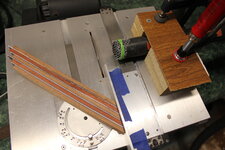

Proxxon FET table saw or the Byrne's one? The proxxon has a tilting arbor and is significantly cheaper. Little concerned with the 80mm (3") blades compared to Byrne's 4" ones. Will the 3" blades be able to cut reasonable thickness of stock?

Proxxon 125E disc sander or Byrne's 5" disc sander? The proxxon is cheaper and has variable speed. I'm little concerned about the build quality. Can you achieve reasonable repeatability in angles with it?

Proxxon DH40 thicknesser (which actually uses blades, not sanding rolls) or Byrne's thickness sander? The proxxon is (surprisingly) more expensive and seems little too coarse (min. achievable Thickness of 3mm) but has power feed. The Byrne's thickness sander can go as thin as 0.0X mm. Did any of you actually needed to go that thin on your segmenting work? Also the thicknesser + the little less capable table saw may actually be a good combo? (Just quickly reduce the thickness of the stock and go to the table saw)?

Also keep in mind that the proxxon I can get with much less shipping costs and import fees. So overall cost is quite significantly cheaper. That includes replacement parts, blades and so on. Many thanks!

I'm debating between some Proxxon equipment and Byrne's model machines (or maybe something else?). Hope any of you with experience can help!

I plan to do mainly segmenting and other complex small work of that kind.

Proxxon FET table saw or the Byrne's one? The proxxon has a tilting arbor and is significantly cheaper. Little concerned with the 80mm (3") blades compared to Byrne's 4" ones. Will the 3" blades be able to cut reasonable thickness of stock?

Proxxon 125E disc sander or Byrne's 5" disc sander? The proxxon is cheaper and has variable speed. I'm little concerned about the build quality. Can you achieve reasonable repeatability in angles with it?

Proxxon DH40 thicknesser (which actually uses blades, not sanding rolls) or Byrne's thickness sander? The proxxon is (surprisingly) more expensive and seems little too coarse (min. achievable Thickness of 3mm) but has power feed. The Byrne's thickness sander can go as thin as 0.0X mm. Did any of you actually needed to go that thin on your segmenting work? Also the thicknesser + the little less capable table saw may actually be a good combo? (Just quickly reduce the thickness of the stock and go to the table saw)?

Also keep in mind that the proxxon I can get with much less shipping costs and import fees. So overall cost is quite significantly cheaper. That includes replacement parts, blades and so on. Many thanks!