Wmcullen

Member

I'm not sure if this process is right or wrong; unique or common. But it works for me and I want to share in case it's interesting. |

20: Polygonal Facets

last post: 19- Facets with a Twist

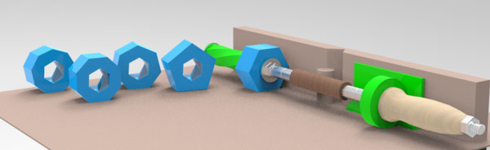

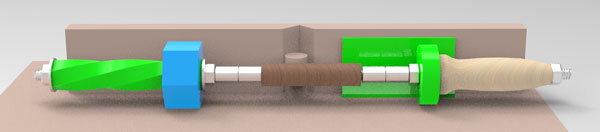

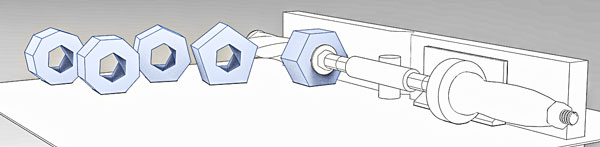

Building on my hexagonal facet jig, I made guides for 5 through 9-sided shapes.

The Jiglast post: 19- Facets with a Twist

Building on my hexagonal facet jig, I made guides for 5 through 9-sided shapes.

More information about its construction can be found in the original post.

It works with my router table and can configure to reference five shapes, including a hexagon which I wrote about last time.

The 5, 7, 8 and 9 sided blanks.

Examples

A 5-sided pen with twisting facets. I think it came out the most angular and interesting to hold.

A 7-sided top that tapers to smooth bottom.

This 8-sided pen has a straight facet until the top inch where it begins to twist.

3D Files

I'm happy to share 3D files with anyone who is curious about what I put together.

I'm not recommending anyone try this themselves but just showing what I've done.

As always the files are provided as-is. File: FacetJig2.zip.

Thanks for looking!

- Cullen