Ok peoples, I reckon I have made enough tests samples of this "wood" that no one has said its name, when some of the pics actually tell what it is...!

Anyway, this is the "famous" McLaren Vale Shiraz red VINE "wood"/material, this have no heartwood or sapwood, is has dead layers and live layers, those ere the ones to replace the dead ones and feed the Vine with the necessary nutrients...!

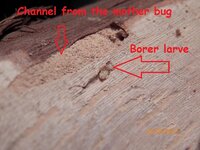

For each batch I filled the vacuum pot (about 80 blanks), cooked them and put them a side, these are treated, if was any borer in the wood, was killed and if the wood was free of it, that's how it will stay, as they (the bugs) won't touch this stuff now...!:wink::biggrin:

I have also made the decision to change my stabilising plans for all the vine I had left, stabilisation cost me about $1.50 (Juice sent to Australia and the most expensive State for Power consumption/prices), I had about 4,000 blanks to do, I then realise that I just can't afford nor I could justify spending $6,000 in the next few weeks to, treat all the vine.

I had already plenty cut but some vines that were never touched, those were some of the least affected and put a side when I first discover the infestation about 6 months ago. I simply kept bringing new wood and pile it on top so, the damn Vine was always under everything and I wasn't sure how I would go about to save the wood.

It simply took me too long to get to it and get the problem solve when I saw the vines that weren't affected 6 months ago now in very nasty condition from the bugs/borer, I wondered how the other blanks I had cut long ago, put is boxes untreated, would be and after getting them all out, I started to got through each blank and make 3 piles, not wholes (borer), a few holes, and plenty of holes...!

The pile with plenty of holes, many in fact totally useless, was the biggest by far, I stopped and though for a while how much money that I don't have, and time that would eat from me to get that lot treated/stabilised, about 2,500 blanks, I quickly come to the conclusion that, I was in no position nor I though it would worth the drama so, loaded the trailer with them, took them to the open storage paddock and set them alight, those damn bores in that lot, were going to be "roasted" good and proper so chances to spread anywhere...!

While the wife stayed keeping and eye on the fire, I went back home and got another big lot, this time were about half of the second pile, the one with a few borer holes, I quickly picked the worse ones, chucked then in the trailer and back to the paddock I went. By then, the first lot was all gone but still hot enough to set alight the second lot.

If did break out hearts to see it burn, after the horrendous amount of work, time and expense to get them in the first place but, sometimes you have to cut your losses and lose once, and not twice...!

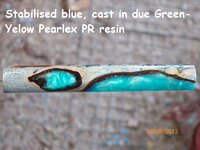

So, what I endup with is about 500 to 600 blanks, most are for Resifills, some are already stabilised blue, and the best ones (no signs of borer) are going to be stabilised in clear/natural juice, no dyes...!

Used 3 gallons these last 2 weeks, I have 4 left and I doubt they will be sufficient but maybe as most of these blanks are quite dense so, not soaking excessively as the very soft stuff, does...!

Even if the Juice I've got left is just enough to do this vine stuff, I have to find some money to order some more gallons from Curtis, there are boxes and boxes of other blanks that will need stabilising next but those, I can do with a little more time as the wood is not infested or affected with any wood eating creatures, thanks goodness for that...

To complete these tests series, I decided to double dye the blanks, soaking the first colour (red, yellow, brown, black) for 18 hours, and then putting them all in the vacuum pot with the blue dye, and give them full vacuum for 5 hours. To note that, this time I did not cook the first colours, what I did was to let the coloured blanks (4 lots of 5 in ice cream containers) to drain overnight before I put them in the blue dyed juice and pull the vacuum on the lot.

I wanted to see if the colour separation was identical to when they are cooked in between colours. After they were cooked, the 4 samples attached show a definitive separation between the first colour and the blue however, the simple soaking of the blanks in the juice dyed, does only cover/fill the borer holes and any other soft patches within the blank, while the blue juice that was been given full vacuum, is the one that always shows in between the "wood" layers...!

So it seems that, letting the wood drain properly from the first soak, and not cooking in between the 2 soakings, it still maintain some colour definition between the first and second colours. This can also be helpful for the amount of soaking the second colour under full vacuum is able to penetrated, as the wood is not "sealed" with the dry/cooked juice from the first colour...!

Now, I can also guarantee that, different results will be experienced depending upon the wood used, that is just expected, huh...???:wink::biggrin:

So, here they are, the last 4 samples, first red/blue, second yellow/blue, third brown/blue and last, black/blue...!

Note: The first colours used, were already mixed for other tests, it was become obvious that, a lot more of the Alumilite dye is require to achieve a strong/solid colour, my mixes were very mild, apart from the blue that I used the half bottle (all I had left) on a gallon of juice...!

Oh well, you game some, you lose some...!

Cheers

George