RGVPens

Member

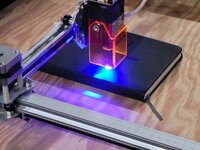

I;m look at adding a laser engraver to my shop. Most threads I found were about a problem...or I couldn't understand what they were talking about! LOL

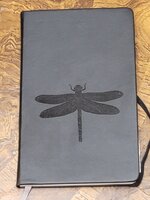

I want to personalize, or a company name, and/or logo on a pen/pencil.

I want to add a name or such on some of my scroll saw work.

I want to engrave on all woods and acrylics/plastics.

I would like to be able to engrave on leather, glass, metal, etc. Might be cool at some later date.

Must be low cost! With scroll saw art, pen making, ring making I can't afford to dump a ton of money into this right now. If it works out I may upgrade later when I know exactly what I want to do with it!

Must be EASY to operate without having to buy software to run it. I use Inkscape with my scroll saw stuff and that would be a plus, or maybe GIMP. Or a machine that comes with a program...?

I know what I would like to be able to do...but have NO IDEA how to go about it. I've never been around one.

Any ideas from those that use one? Or those that have used more than one and can tell me what brand/model to stay away from?

I know a guy on the east coast that uses a NEJE, ??, and it works for him. I've also seen Atomstack P7, xToolD1, and a bunch of others advertised.

Thanks!

I want to personalize, or a company name, and/or logo on a pen/pencil.

I want to add a name or such on some of my scroll saw work.

I want to engrave on all woods and acrylics/plastics.

I would like to be able to engrave on leather, glass, metal, etc. Might be cool at some later date.

Must be low cost! With scroll saw art, pen making, ring making I can't afford to dump a ton of money into this right now. If it works out I may upgrade later when I know exactly what I want to do with it!

Must be EASY to operate without having to buy software to run it. I use Inkscape with my scroll saw stuff and that would be a plus, or maybe GIMP. Or a machine that comes with a program...?

I know what I would like to be able to do...but have NO IDEA how to go about it. I've never been around one.

Any ideas from those that use one? Or those that have used more than one and can tell me what brand/model to stay away from?

I know a guy on the east coast that uses a NEJE, ??, and it works for him. I've also seen Atomstack P7, xToolD1, and a bunch of others advertised.

Thanks!

Last edited: