This is how I've set up my pot. I was going to copy others but I knew it would just be a matter of time or distraction that made me open the wrong valve.[:I] My compressor has a regulated output so I did away with the one supplied with the pot.

My compressor has a regulated output so I did away with the one supplied with the pot.

This pic show the two Hanson connectors, one for the gauge and the other the input hose. I kept the supplied relief valve.

This pic shows the gauge I will probably use for now. It is good for pressure or vacuum.

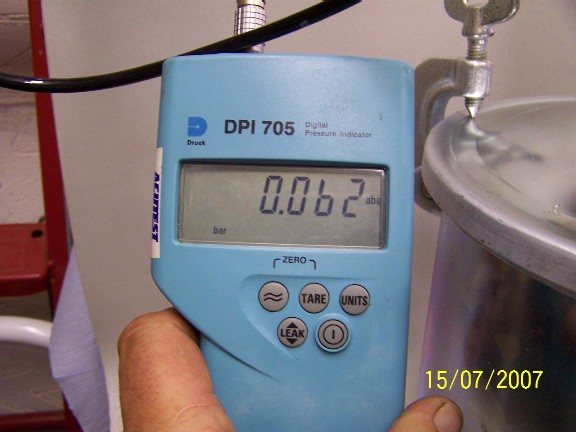

This pic shows how I substituted the dial gauge for an electronic transducer and digital gauge so I could test the pot before use. There is no pressure in the tank at the moment.

This pic show the inside of the lid. I have removed the sealing ring so that I could heat up the thread sealant and remove the tube. I fitted the elbow on the inside to divert airflow. I also cleaned the recess for the seal.

Here I have cleaned and lubricated both sides of the seal before putting it back

This is the vacuum I achieved after about 4 minutes. I was too impatient to see how long it would hold, but I had no change after 3 hours, so I'm happy with that.

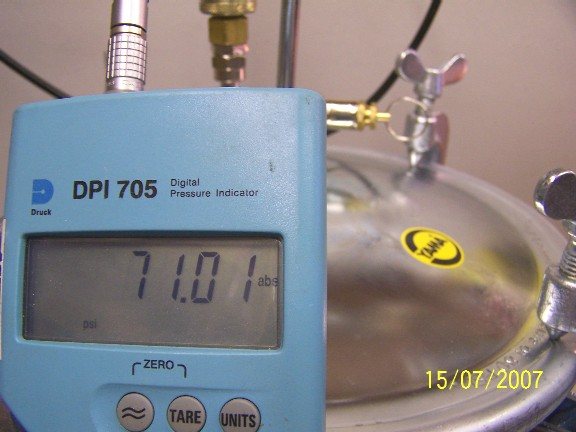

Next I wanted to prove the pressure relief valve. It opened at about <s>75psig</s> 75psi abs and then I removed the input hose. The valve stayed open till about <s>70psig</s>70psi abs. It kept this pressure for 3 hours as well so I'm happy.

And finally, before I go and play with it, I cut a hole in one of my benches and dropped it in, so that I couldn't knock it over. I'll make a neater hole and a replacable flush disc to close the hole later

Edited the psig to psi abs and I think Hanson could be Hansen, before the sharp eyed folks spot it[:I]

This pic show the two Hanson connectors, one for the gauge and the other the input hose. I kept the supplied relief valve.

This pic shows the gauge I will probably use for now. It is good for pressure or vacuum.

This pic shows how I substituted the dial gauge for an electronic transducer and digital gauge so I could test the pot before use. There is no pressure in the tank at the moment.

This pic show the inside of the lid. I have removed the sealing ring so that I could heat up the thread sealant and remove the tube. I fitted the elbow on the inside to divert airflow. I also cleaned the recess for the seal.

Here I have cleaned and lubricated both sides of the seal before putting it back

This is the vacuum I achieved after about 4 minutes. I was too impatient to see how long it would hold, but I had no change after 3 hours, so I'm happy with that.

Next I wanted to prove the pressure relief valve. It opened at about <s>75psig</s> 75psi abs and then I removed the input hose. The valve stayed open till about <s>70psig</s>70psi abs. It kept this pressure for 3 hours as well so I'm happy.

And finally, before I go and play with it, I cut a hole in one of my benches and dropped it in, so that I couldn't knock it over. I'll make a neater hole and a replacable flush disc to close the hole later

Edited the psig to psi abs and I think Hanson could be Hansen, before the sharp eyed folks spot it[:I]