rherrell

Member

This thread... https://www.penturners.org/threads/60-degree-centers.180555/#post-2211416 got me to thinking about grinding beat up old live centers. Dead centers are no problem but live centers need to be held in the tailstock and the center portion needs to be spun somehow. Spinning the center portion is the problem and is just the kind of problem I like solving.

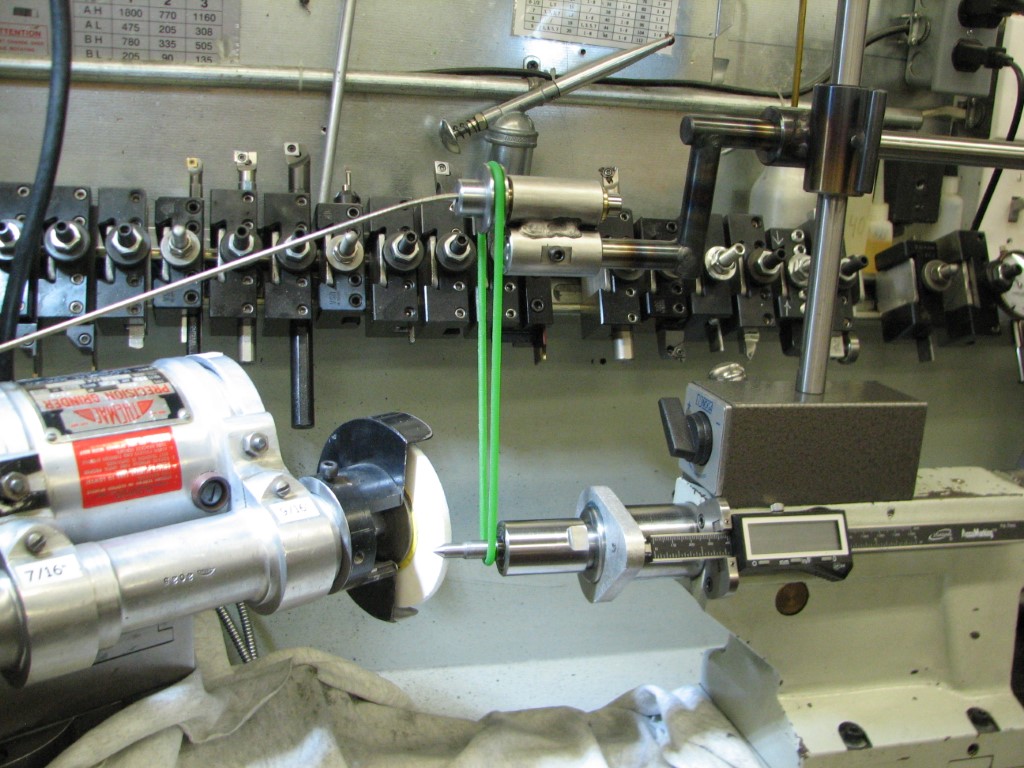

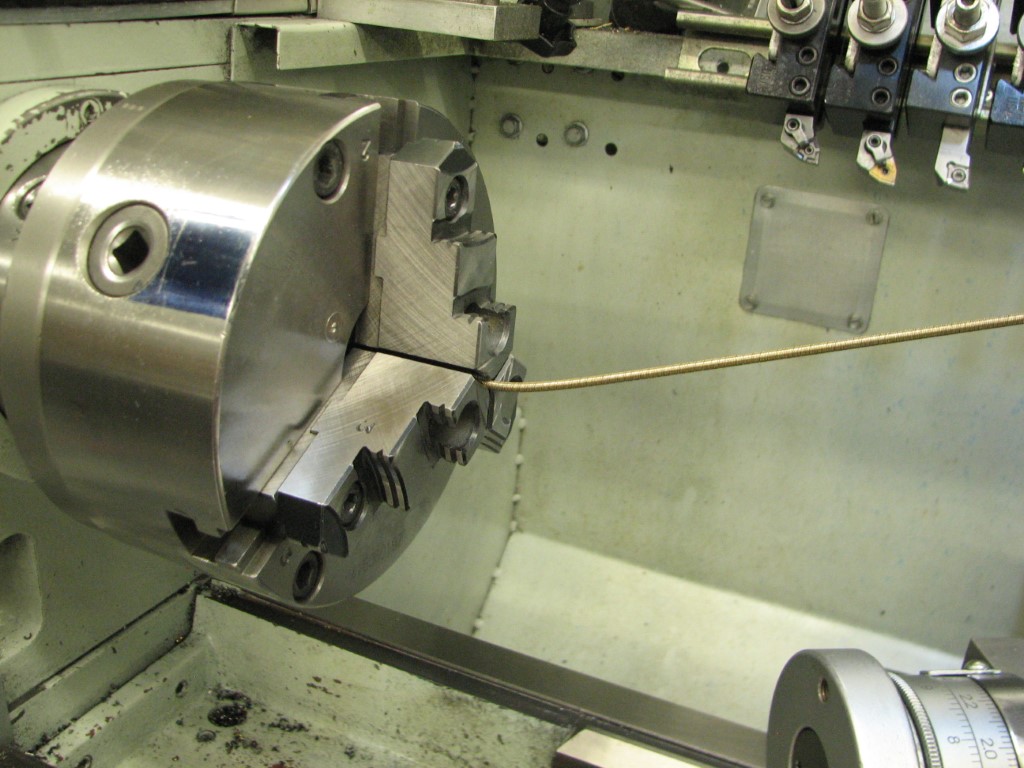

Here's my "contraption"...

I made a pulley and a spindle and mounted it on a magnetic DI holder on my tailstock. That wire going into the spindle is actually the inside shaft of my Dremel Flexible Shaft tool, which I have never use anyhow. It's connected to my lathe chuck and that's how I spin the spindle.

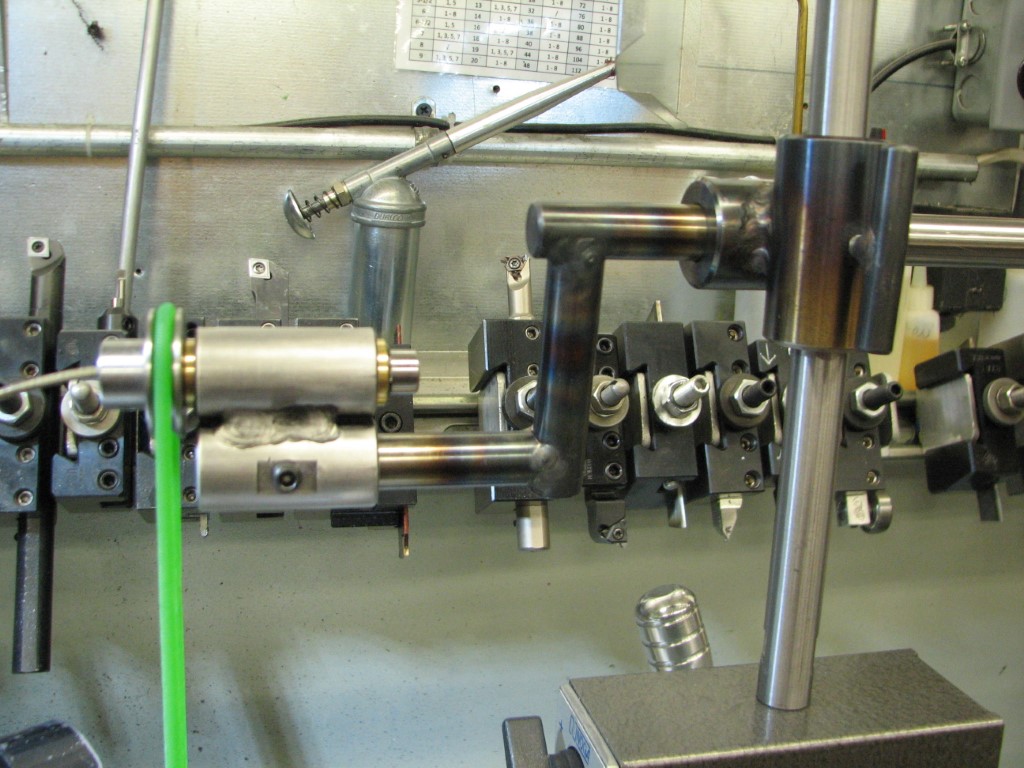

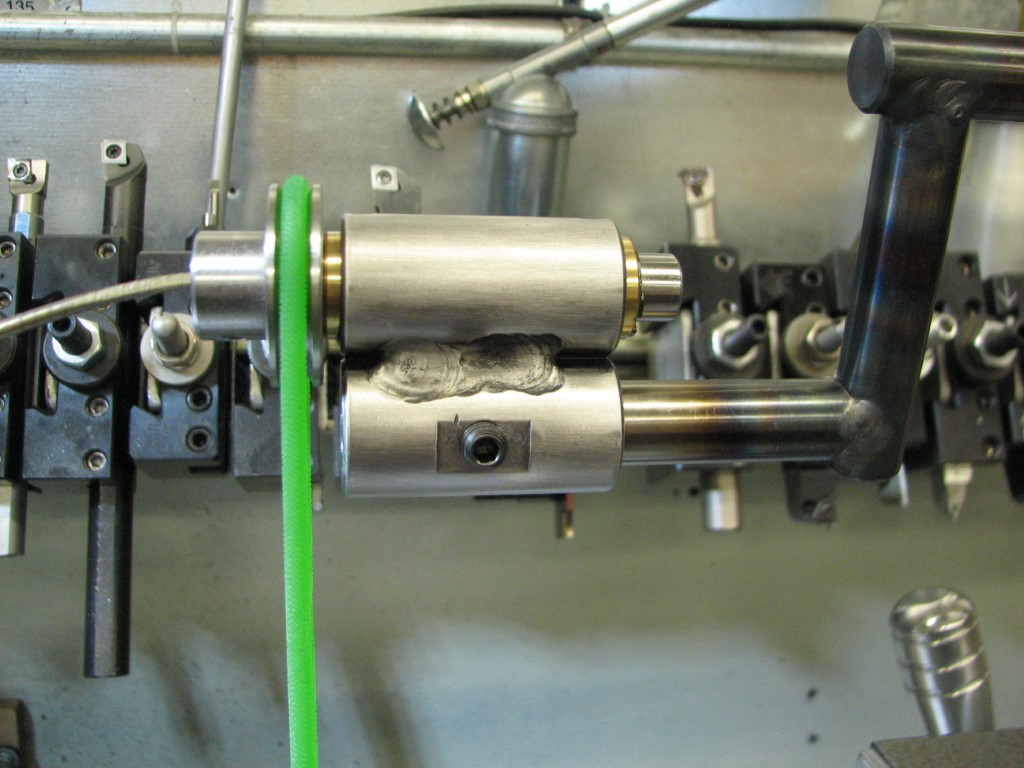

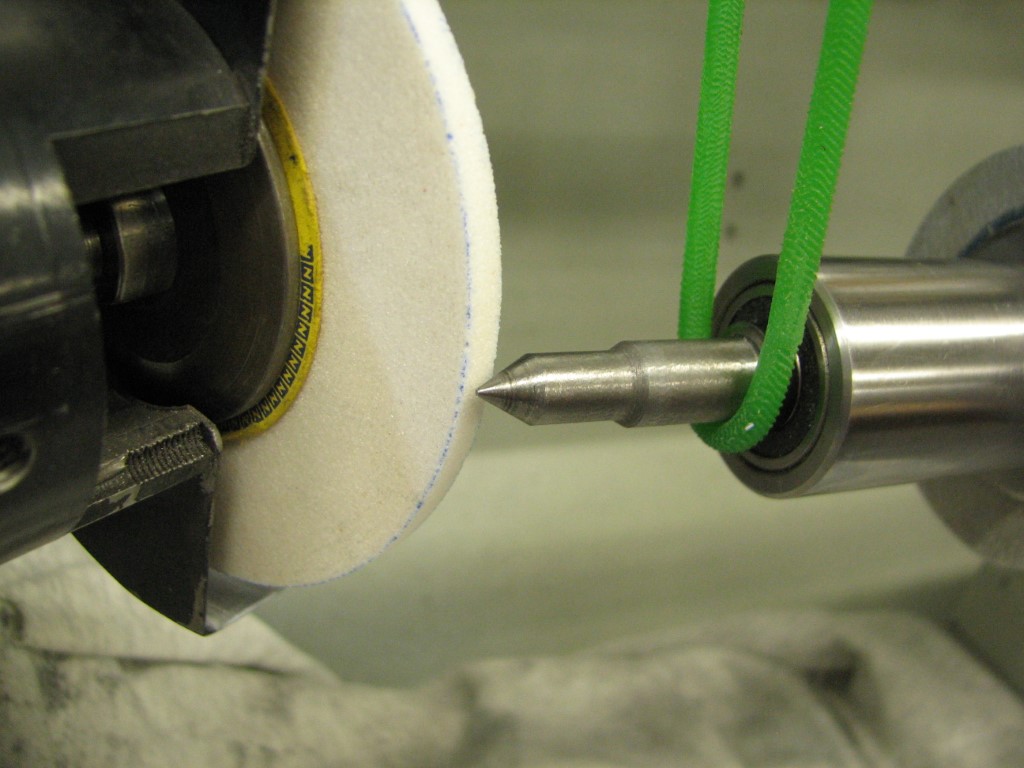

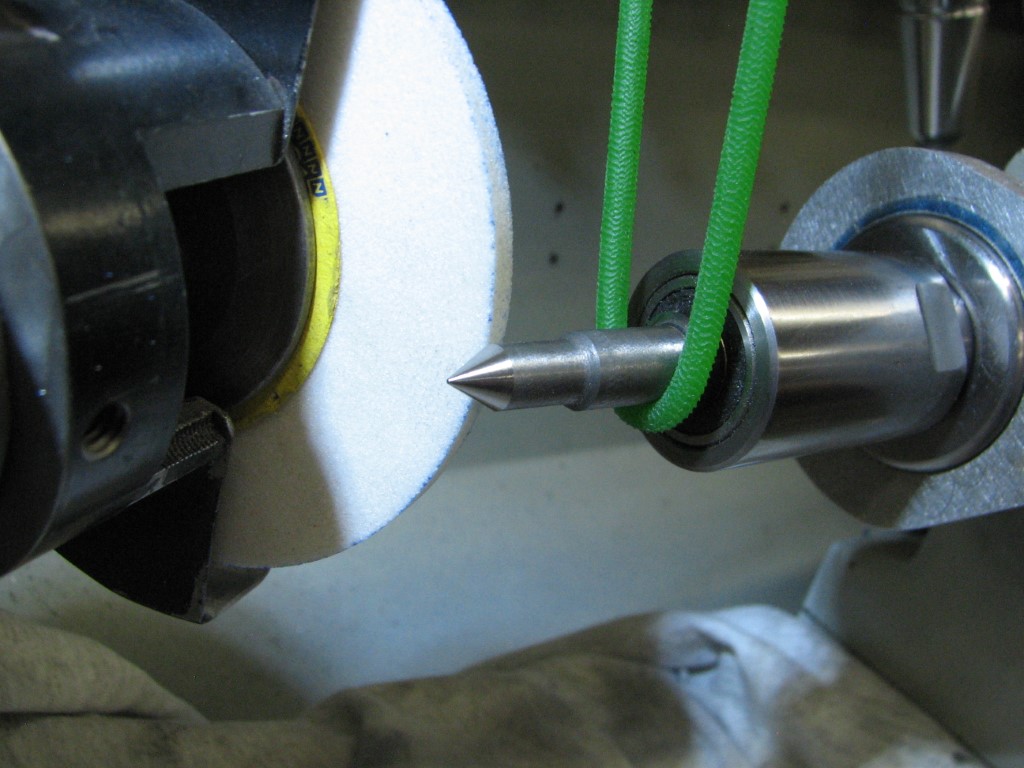

Here are some close up shots...

Here's a before and after shot of my first attempt and it works really well!!

So now I guess I'm in the live center grinding business!!!

Thanks for looking.

Here's my "contraption"...

I made a pulley and a spindle and mounted it on a magnetic DI holder on my tailstock. That wire going into the spindle is actually the inside shaft of my Dremel Flexible Shaft tool, which I have never use anyhow. It's connected to my lathe chuck and that's how I spin the spindle.

Here are some close up shots...

Here's a before and after shot of my first attempt and it works really well!!

So now I guess I'm in the live center grinding business!!!

Thanks for looking.