qquake

Member

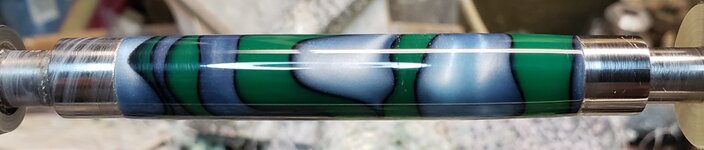

This is an AA blank from Woodcraft called Irish Hill. It's a good looking blank. First I used 220-320-400-600 wet, then polished it with Tri-M-Ite. It polished up nicely. But I'm trying to put a matte finish on it. So I went back and used the first grade of Tri-M-Ite only, but you can't hardly see a difference.