rixstix

Member

I didn't realize there would be questions regarding using my lathe(s) as specialized, mini table saws so here are pics.

The backstory is that my wife and I make precious metal jumprings. Not a huge industry so most tools and equipment tend to be individually made for purpose. Business grew to the point where I spent more time adjusting a small handsaw for each metal and coil size than I spent actually cutting the coil. My pen lathe was used as the first test and followed with 4 additional after the kinks were mostly ironed.

7 years ago, my pen lathe got converted to a specialized, mini tablesaw which uses both 1.5" and 1.75" diameter blades. 0.006", 0.008", 0.010" and occasionally a 0.004" thick HSS blade. That grew to 5 lathes setup. 2 variable speed and 3 Jet 1014 fixed speed, each setup slightly different. PSI tech guys were great in talking me through adjusting an internal setting to lower the bottom speed to about 50 rpm for sawing Titanium coils. 2020 was pretty slow and we made a decision which allowed me to restore one of the lathes to its original purpose in late December. Now I have 7 years of catching up to do here.

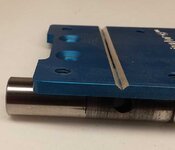

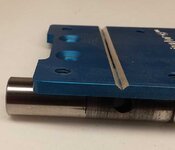

Custom Arbor by Rick Herrell

Specialized Table

Custom Toolpost by Rick Herrell

Mini Saw ready for work. Toolpost allows blade height adjustment.

Coil of 16awg 14kt yellow gold-filled wire which is a misnomer since the gold is on the outside, not the filling.

Coil cutting in progress

Saw output ready for polish and hardening (not quite 3 ounces)

The backstory is that my wife and I make precious metal jumprings. Not a huge industry so most tools and equipment tend to be individually made for purpose. Business grew to the point where I spent more time adjusting a small handsaw for each metal and coil size than I spent actually cutting the coil. My pen lathe was used as the first test and followed with 4 additional after the kinks were mostly ironed.

7 years ago, my pen lathe got converted to a specialized, mini tablesaw which uses both 1.5" and 1.75" diameter blades. 0.006", 0.008", 0.010" and occasionally a 0.004" thick HSS blade. That grew to 5 lathes setup. 2 variable speed and 3 Jet 1014 fixed speed, each setup slightly different. PSI tech guys were great in talking me through adjusting an internal setting to lower the bottom speed to about 50 rpm for sawing Titanium coils. 2020 was pretty slow and we made a decision which allowed me to restore one of the lathes to its original purpose in late December. Now I have 7 years of catching up to do here.

Custom Arbor by Rick Herrell

Specialized Table

Custom Toolpost by Rick Herrell

Mini Saw ready for work. Toolpost allows blade height adjustment.

Coil of 16awg 14kt yellow gold-filled wire which is a misnomer since the gold is on the outside, not the filling.

Coil cutting in progress

Saw output ready for polish and hardening (not quite 3 ounces)

Last edited: