RicardoPG

Member

Hello everyone!

I recently started pen turning with a metal lathe and wanted to ask if anyone exclusively uses their lathe for making all of the threads, such as those inside the caps and barrels (for the section), or if most people prefer using taps and dies.

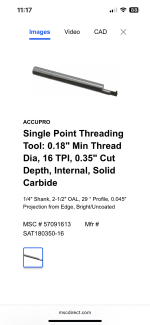

While I find that taps and dies might be the more straightforward option, they can limit the dimensions and thread types available. However, I'm struggling to find tools small enough to bore the inside of a cap or section and to thread it, especially since I want to use carbide bits. I've discovered that HSS (high-speed steel) tends to not work well - it wears areally fast - with the ebonite I'm turning.

I've come across small tools like Thinbit inserts, but unfortunately, I believe they are only sold in the US, and I am located in Europe.

What are your thoughts on using only the lathe for threading?

I recently started pen turning with a metal lathe and wanted to ask if anyone exclusively uses their lathe for making all of the threads, such as those inside the caps and barrels (for the section), or if most people prefer using taps and dies.

While I find that taps and dies might be the more straightforward option, they can limit the dimensions and thread types available. However, I'm struggling to find tools small enough to bore the inside of a cap or section and to thread it, especially since I want to use carbide bits. I've discovered that HSS (high-speed steel) tends to not work well - it wears areally fast - with the ebonite I'm turning.

I've come across small tools like Thinbit inserts, but unfortunately, I believe they are only sold in the US, and I am located in Europe.

What are your thoughts on using only the lathe for threading?