@keithbyrd - CONGRATULATIONS on your new lathe !!! . . . You are going to have MUCH FUN with it !! . A Sieg lathe by the looks . . like mine !

I do NOT recommend buying the multi-shaped cutter sets that are commonly sold in a variety pack by some vendors -- you don't need most that are in the set - - and besides that, those variety-pack carbide cutters tend to break easily and often. . The pack may not even include a round.

I see such a set (red) in the picture you showed.

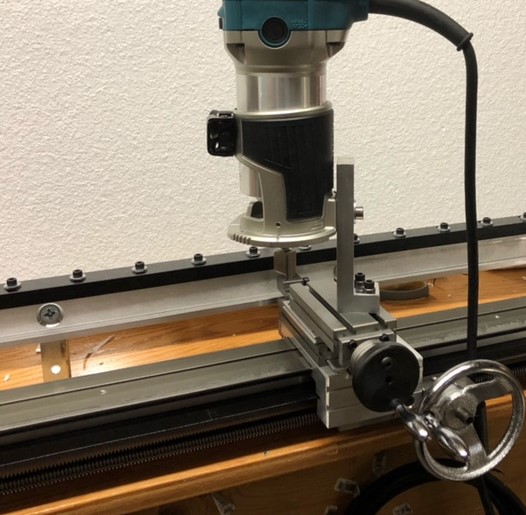

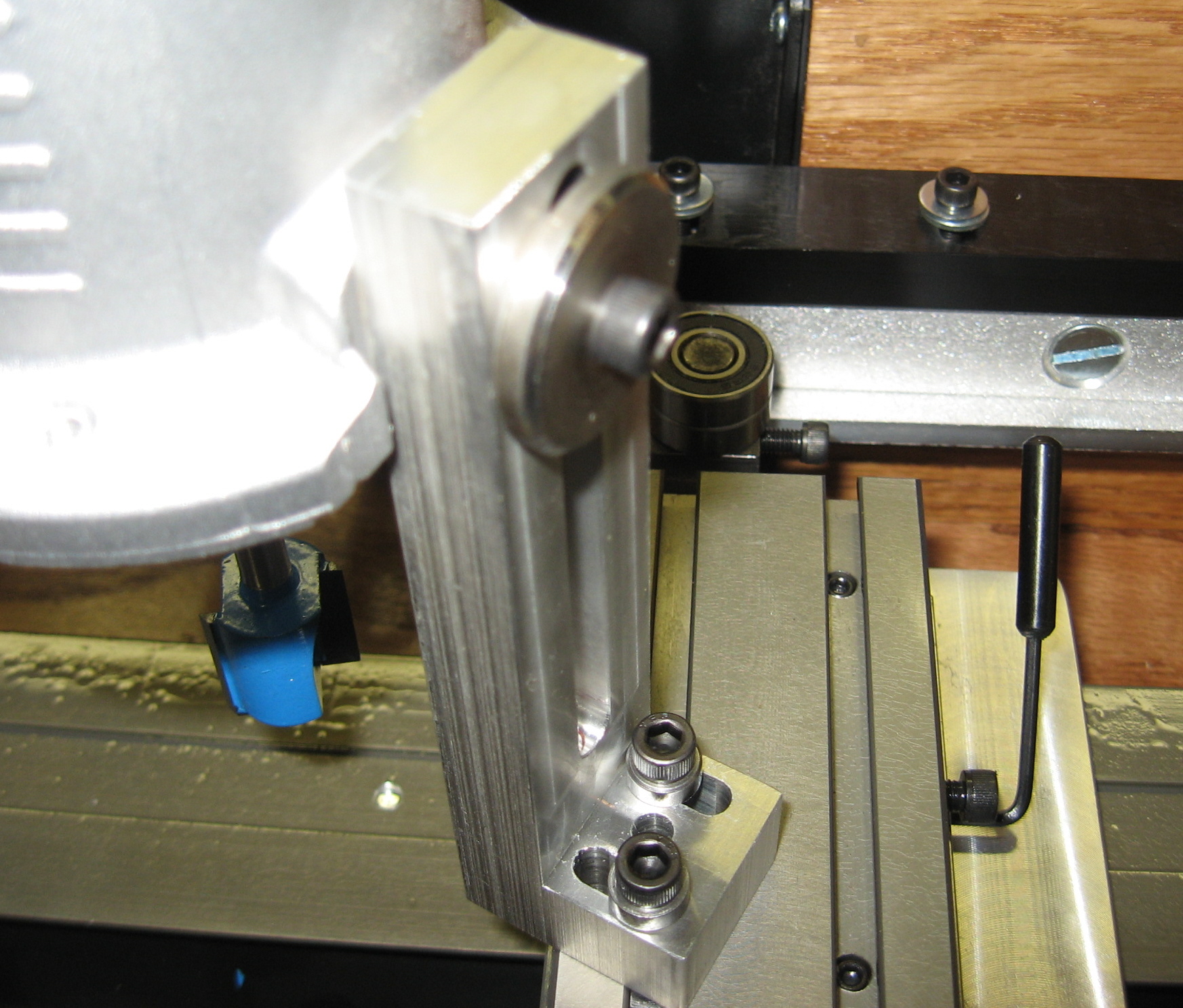

The cutting tool that I have used for 10 years (some infrequent replacements during that period) is a round carbide cutter, 11 mm diameter, supplied by Global Tooling in Portland, OR, and fitted to a straight 5/16 tool holder bar (not quite square cross section) which was made by Ken Ferrell (IAP member who I have not seen on-line for several years now).

I would suggest that you try to get Rick Herrell ( Username: rherrell ) to make a cutter like this for you, using the same Global Tooling carbide.

I order from Global Tooling by phone, as needed. . The people there are very helpful and very prompt to ship.

I use this cutter for everything I make.- "plastic", wood, aluminum and brass. . . It is a superb workhorse for pens !!!

I believe this is the cutter that I buy, as needed. . . I will check to be sure - - contact me directly for further info.

Woodturning carbide cutter. 11 mm diameter x 4 mm thick round carbide insert knife. Commonly used in wood turning applications. Round cutters are generally used for inside curves. Made using long wearing solid C3 carbide and polished for smoother cutting and longer life.

www.globaltooling.com