Hello,

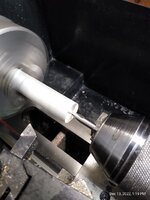

I have a question in my penmaking journey. I am getting better at the whole process and I managed to make some pens with multiple segments. I made two parts which are attached to one another with threads. What I wanna do now is make brass / aluminium accents. I was thinking of 1 mm brass rivets ( I dont know how they are called in English) the ones you use with a bolt and screw. I ordered some M14 with a hole of 10mm. Or should I order a small plate of brass and aluminium and drill holes and cut em?

Do you make 2 parts without threads and then glue it together with the rivet inbetween or make threads and glue it to the male part?

What's the way to go about it? If I know how to do it I can practise.

Niels

I have a question in my penmaking journey. I am getting better at the whole process and I managed to make some pens with multiple segments. I made two parts which are attached to one another with threads. What I wanna do now is make brass / aluminium accents. I was thinking of 1 mm brass rivets ( I dont know how they are called in English) the ones you use with a bolt and screw. I ordered some M14 with a hole of 10mm. Or should I order a small plate of brass and aluminium and drill holes and cut em?

Do you make 2 parts without threads and then glue it together with the rivet inbetween or make threads and glue it to the male part?

What's the way to go about it? If I know how to do it I can practise.

Niels