Hi all.

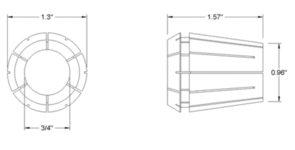

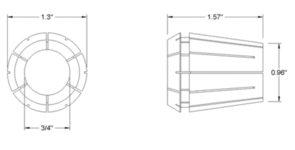

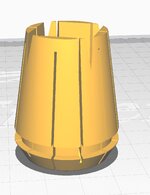

Printing was a little trickier than I expected, even more so for the .75" version.

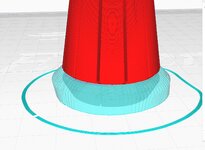

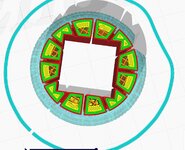

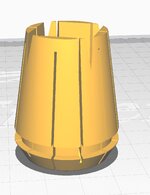

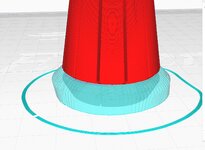

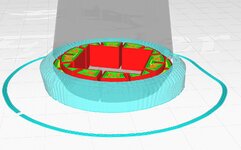

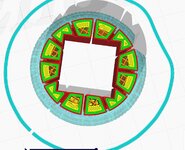

Some screenshots to show what I mean:

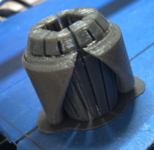

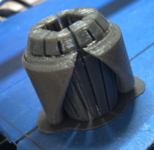

The walls get really thin with the ,75 version. The blue ABS filament seems to have an issue on my 3d printer. The collet won't stay in one piece. I guess it's still usable if you hold the sections together as you put collet in the chuck.

The grey and the green PLA seem to work decently with the green PLA giving the best results at a printing resolution of .12mm per layer.

The hardest past was figuring out the best support structure to use. When 3d printing an item you have to have the printer print support under over hanging areas. The down side is that the supports can be hard to remove.

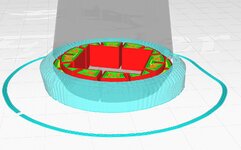

The teal area are the supports it will print. The other two images are cross sections looking down.

You can see an example of what happens when you don't use supports properly, the area around the top rim of the collet gets stringy and falls apart.

So now I have a .50 and .75 collet ready to be tested.

BTW, the final settings of .12mm layer height with 100% infill cause each collet to take about 4.5 hours to print. And you can only print one collet at a time. :-(

Not sure the cheapest way to mail. I will need to get boxes, should I use priority mail small boxes? Thoughts?