calabrese55

Member

Well hell I got to vent.

I am new to pen making, (not woodworking) and want to also make some of my own epoxy blanks.

Just bought some Aluminite Clear Slow and knew I would need a pressure pot to make it work. Been looking and was set on California Air Tools. I really don't mind spending extra $$$ for good quality tools however I am not made of money and i could not push the button on the California pot for maybe another month. Unfortunately a Harbor Freight store just opened 12 miles from me yup looking for instant gratification so off I go to HF.

This was what followed me home

https://www.harborfreight.com/2-1-2-half-gallon-pressure-paint-tank-66839.html

A few more bucks to buy some fittings to modify the HF paint pot.

If you want to know how I did it just check out Jake Thompson on YouTube. I mostly played off his mods , he is really good at emptying the complete bag on stuff , very worth your time.

Here is his HF pot vid same pot I bought today.

OK now to the heartache.

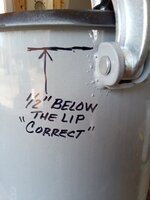

See the pics here . One set of the tabs that the clamp is attached to was welded to the tank body 1/4 inch higher than the other 3 clamp assemblies. It is off enough that the screw runs out of travel before sufficient force can be applied by that clamp.

Ok no biggie the fix is simple a little grinding.....the pictures below will tell the story.

Next the pressure regulator is useless. All they way in or all out absolutely no influence on the tank pressure up or down.

OK I can use the regulator on my compressor and set it at 30 PSI for openers.

The safety valve pops off at about 15 - 18 PSI simple adjustment and it is good however the tank now LEAKS at the gasket in one specific area starting at 20 PSI

I am pi$$ed off now .....how can something be so god awful crappy well below the expectation I had for the HF cheapie price of $99.99.

I know it wasn't a Ferrari when I drove it home but holy crap it should at least make it around the track for a couple of laps.

There is a section about 10% of the circumference blowing out at 20 PSI. I pulled the gasket, other than some weld splatter in the gasket groove I see no real cause. At that point I went home from my shop as there is a canal about a few hundred yards from my shop and I was wondering if the darn thing would possibly float or be the boat anchor I think it is.

I will get back to it tomorrow but for now if ANYONE IT THINKING ABOUT BUYING THIS HF PRODUCT BE WARE it looks like it doesn't even measure up to anyone's lowest expectation of a product made in China.

I will let you know if I test it for water tight qualities

calabrese55

I am new to pen making, (not woodworking) and want to also make some of my own epoxy blanks.

Just bought some Aluminite Clear Slow and knew I would need a pressure pot to make it work. Been looking and was set on California Air Tools. I really don't mind spending extra $$$ for good quality tools however I am not made of money and i could not push the button on the California pot for maybe another month. Unfortunately a Harbor Freight store just opened 12 miles from me yup looking for instant gratification so off I go to HF.

This was what followed me home

https://www.harborfreight.com/2-1-2-half-gallon-pressure-paint-tank-66839.html

A few more bucks to buy some fittings to modify the HF paint pot.

If you want to know how I did it just check out Jake Thompson on YouTube. I mostly played off his mods , he is really good at emptying the complete bag on stuff , very worth your time.

Here is his HF pot vid same pot I bought today.

OK now to the heartache.

See the pics here . One set of the tabs that the clamp is attached to was welded to the tank body 1/4 inch higher than the other 3 clamp assemblies. It is off enough that the screw runs out of travel before sufficient force can be applied by that clamp.

Ok no biggie the fix is simple a little grinding.....the pictures below will tell the story.

Next the pressure regulator is useless. All they way in or all out absolutely no influence on the tank pressure up or down.

OK I can use the regulator on my compressor and set it at 30 PSI for openers.

The safety valve pops off at about 15 - 18 PSI simple adjustment and it is good however the tank now LEAKS at the gasket in one specific area starting at 20 PSI

I am pi$$ed off now .....how can something be so god awful crappy well below the expectation I had for the HF cheapie price of $99.99.

I know it wasn't a Ferrari when I drove it home but holy crap it should at least make it around the track for a couple of laps.

There is a section about 10% of the circumference blowing out at 20 PSI. I pulled the gasket, other than some weld splatter in the gasket groove I see no real cause. At that point I went home from my shop as there is a canal about a few hundred yards from my shop and I was wondering if the darn thing would possibly float or be the boat anchor I think it is.

I will get back to it tomorrow but for now if ANYONE IT THINKING ABOUT BUYING THIS HF PRODUCT BE WARE it looks like it doesn't even measure up to anyone's lowest expectation of a product made in China.

I will let you know if I test it for water tight qualities

calabrese55

Attachments

-

low welded 1.jpg240 KB · Views: 431

low welded 1.jpg240 KB · Views: 431 -

low welded 2.jpg263.6 KB · Views: 357

low welded 2.jpg263.6 KB · Views: 357 -

correctly welded 3.jpg201.2 KB · Views: 333

correctly welded 3.jpg201.2 KB · Views: 333 -

standard clamp before grinding mods.jpg477.6 KB · Views: 349

standard clamp before grinding mods.jpg477.6 KB · Views: 349 -

clamp after grinding 4.jpg169.4 KB · Views: 328

clamp after grinding 4.jpg169.4 KB · Views: 328 -

sufficient travel after clamp grinding mod.jpg256.2 KB · Views: 322

sufficient travel after clamp grinding mod.jpg256.2 KB · Views: 322