Mach4

Member

When I saw the post by jalbert a couple weeks ago on his amazing Byzantine Bracelet, I thought that this would make for a very interesting pen….

So I set out to see if I could accomplish something along that line. I decided to try 3D printing a pen using that basic concept. I first thought about designing one in CAD but actually found an OpenScad file that TrenchCoatGuy had uploaded to Thingiverse.

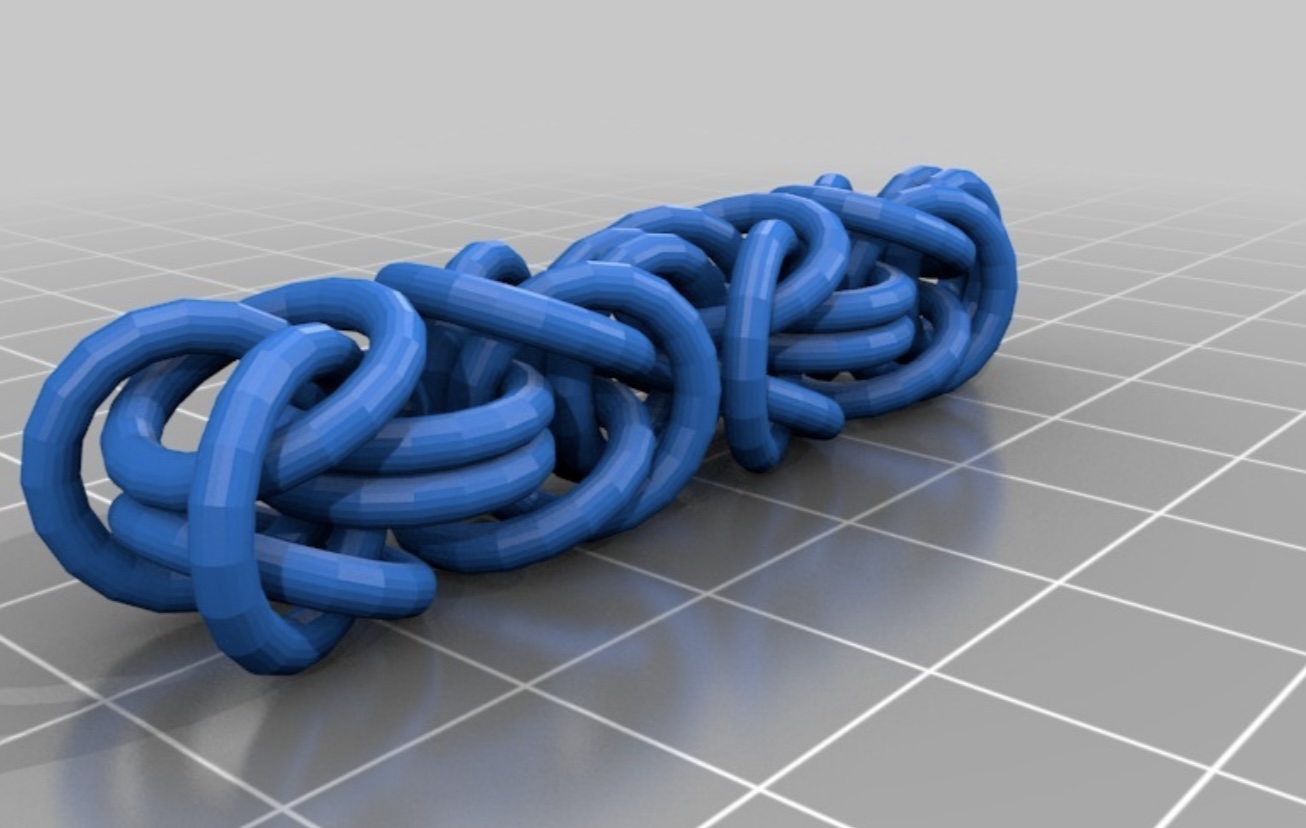

Obviously you can't make a pen out of a chain, so I opened the file in OpenScad and modified it by making the ring wire diameter larger, adding links to the model and decreased the aspect ratio so the rings would overlap each other a bit to create a rigid item rather than a chain. I exported the model as an .stl file and printed it to see how it might work.

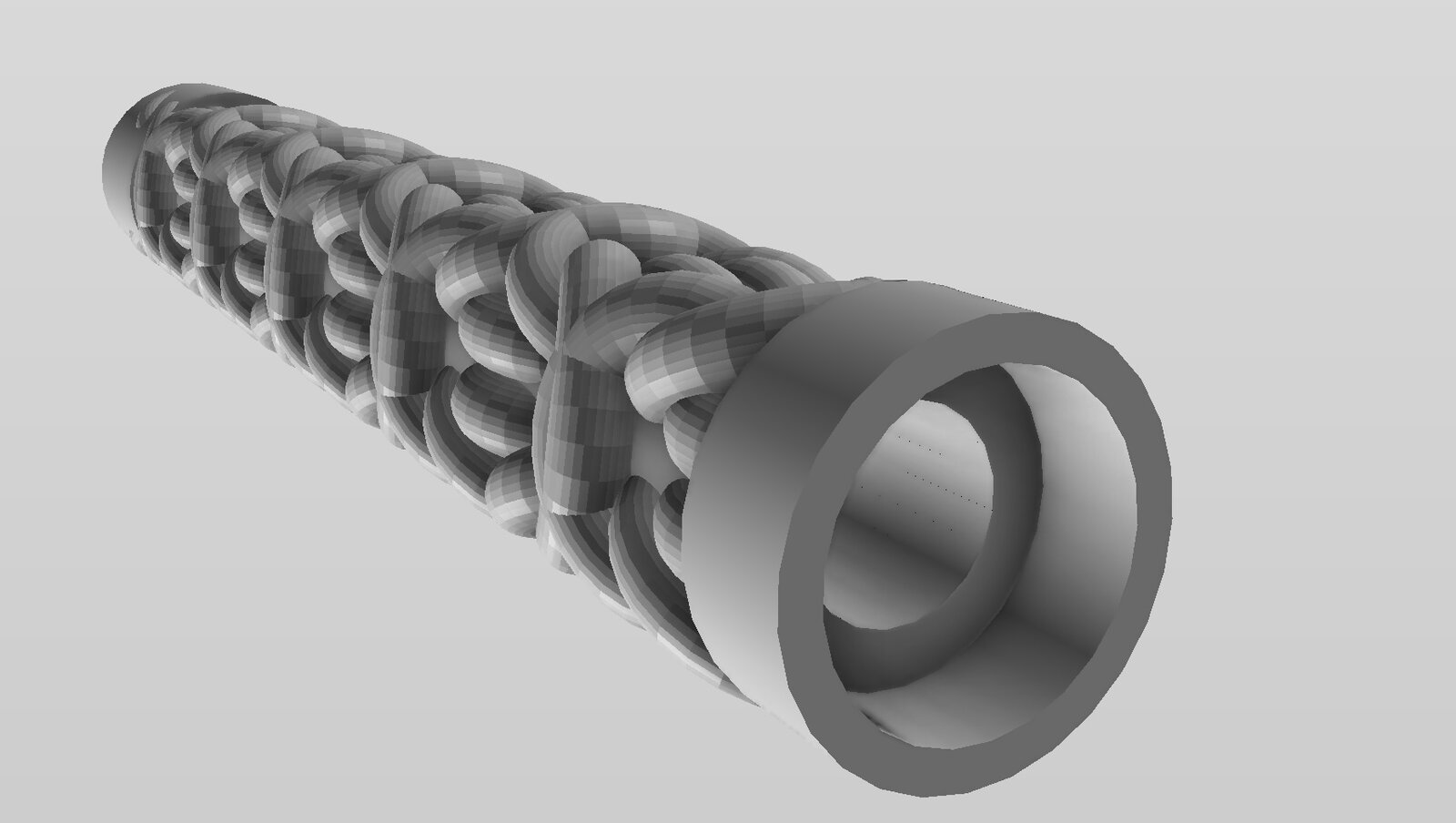

It looked good and was the right size so I imported it into Fusion 360 and converted the mesh into a brep solid where I could work on it. I modeled a ring on the front and back for the tip and back end. I then "drilled" it through to accept 7mm brass tubes and Slimline transmission, extruded a "wall" around the hole to provide additional support and designed the tip and the back end.

Finally I 3D printed the design and finished it in a metallic paint and a black wash to give it some depth. All in all a fun and challenging exercise based on a members silversmithing project. Here's the final product….

So I set out to see if I could accomplish something along that line. I decided to try 3D printing a pen using that basic concept. I first thought about designing one in CAD but actually found an OpenScad file that TrenchCoatGuy had uploaded to Thingiverse.

Obviously you can't make a pen out of a chain, so I opened the file in OpenScad and modified it by making the ring wire diameter larger, adding links to the model and decreased the aspect ratio so the rings would overlap each other a bit to create a rigid item rather than a chain. I exported the model as an .stl file and printed it to see how it might work.

It looked good and was the right size so I imported it into Fusion 360 and converted the mesh into a brep solid where I could work on it. I modeled a ring on the front and back for the tip and back end. I then "drilled" it through to accept 7mm brass tubes and Slimline transmission, extruded a "wall" around the hole to provide additional support and designed the tip and the back end.

Finally I 3D printed the design and finished it in a metallic paint and a black wash to give it some depth. All in all a fun and challenging exercise based on a members silversmithing project. Here's the final product….