ColeCadorette

Member

Hello everyone!

This is my first post in this forum. And from what I've seen I'm super excited for this discussion.

I'm looking to get into kitless pen making. I've made a few slimlines at my local makerspace but I've always adored fountain pens so I want to make my own (.........cuz I can't afford the number of montblancs I want). I have very little experience but i don't mind doing my research and taking on a challenge.

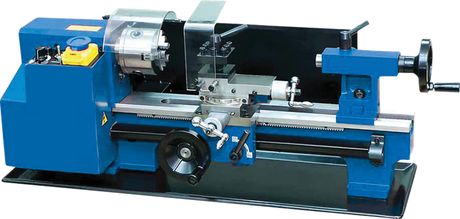

So I know the topic of "what do I need to go kitless" has been rehashed many a time but I've not seen many with specifically what combo of tools to buy. From my reading I've figured out I probably need the items in this list:

docs.google.com

docs.google.com

But I'm not sure if all these tools are exactly what I need or even work together and before I drop that amount of money I'd like to get a second opinion.

So is this list complete? Are there better or cheaper alternatives? Where can I save money?

Note I've gone with amazon mostly because I have prime and one day shipping makes everything better lol but if you know any other sources that are cheaper pls let me know.

Also I left out the dies I plan to model the pen this week in a CAD package and make those decisions then.

Thanks for any help you can provide

Cole Cadorette

This is my first post in this forum. And from what I've seen I'm super excited for this discussion.

I'm looking to get into kitless pen making. I've made a few slimlines at my local makerspace but I've always adored fountain pens so I want to make my own (.........cuz I can't afford the number of montblancs I want). I have very little experience but i don't mind doing my research and taking on a challenge.

So I know the topic of "what do I need to go kitless" has been rehashed many a time but I've not seen many with specifically what combo of tools to buy. From my reading I've figured out I probably need the items in this list:

Kitless pen making supplies

But I'm not sure if all these tools are exactly what I need or even work together and before I drop that amount of money I'd like to get a second opinion.

So is this list complete? Are there better or cheaper alternatives? Where can I save money?

Note I've gone with amazon mostly because I have prime and one day shipping makes everything better lol but if you know any other sources that are cheaper pls let me know.

Also I left out the dies I plan to model the pen this week in a CAD package and make those decisions then.

Thanks for any help you can provide

Cole Cadorette