Hate to see an argument develop between two people who both do excellent work that I enjoy seeing , bit I believe there are some considerations that haven`t entered the discussion , and should .

You both live in vastly different climates , and that greatly affects wood stability . Tehachapi`s average annual precipitation is 11 inches , most of it in the winter . Wood expansion in both directions will be much less under those conditions , and the difference between longitudinal and radial will be less .

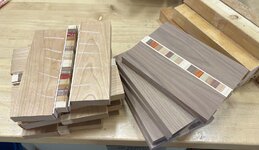

Given that , I can well believe that Mark has seen zero problems , as probably a large number of his customers live in a similar climate . But , I would also suggest that those receiving a gift of one of his beautiful cheeseboards who live in an area like Robert`s would not complain should it develop irregularities .

There may be one other factor . The white wood bordering the cross cut pieces may have lower longitudinal expansion than the wood making up the bulk of the board . That could alleviate the potential problem , but I doubt that approach would be enough to guarantee no problems under Robert`s conditions .

Glues have definitely improved - the current discussion on oily glues is proof of that . But , wood is wood , and will behave accordingly , unless stabilized , and then it only looks like wood .

Enough one finger typing for today .