OKLAHOMAN

Member

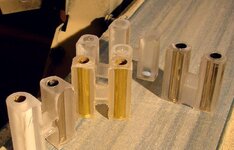

A few weeks ago Charlie (NewLondon88) wanted some Beta testers for his idea of a mold that you would not have to have to use corks, or stoppers, also would not have to fill with BB's or clay to keep the resin out of the tubes when casting skins, labels or any other tubed casting.

As everyone stepped backward one step I fell asleep and remained where I was so I received the mold a week or so ago and just now had a chance to test it.

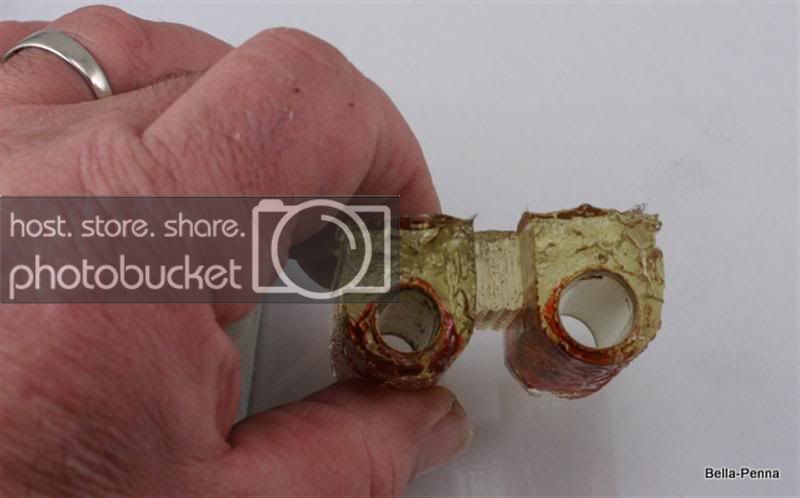

This mold was a prototype and only held 2 tubes for one pen. It was not made for resale and was rough looking but functional.

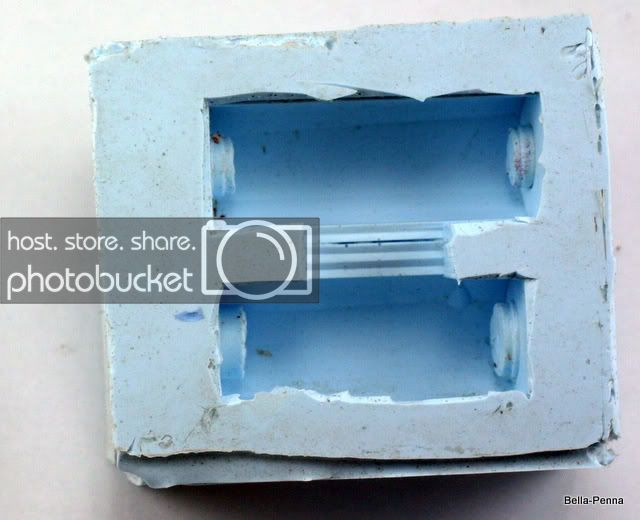

I was skeptical that under pressure the built in stoppers would keep resin out of the tubes. I usually fill my tubes with clay and use corks glued to 1x1 thin strips of wood (cut up Paint stirrers). The mold eliminated the use of clay, corks and 1x1's and as a side benefit 50% or more PR.But would it work?

It's been a little cold the last few days so I heated the PR in my toaster oven to get it thin and pourable as water thinking that the thinner the pr the more chance that it would seep into the tubes under pressure.

Mixed my activator, poured and placed into the pot at 40PSI for 2 hrs. below are pictures of the final results. Not a drop of PR in the tubes.

Below are the results in pictures:

First the Mold:

Told you it's a prototype:wink:

Second, the pour:

Still not impressed?

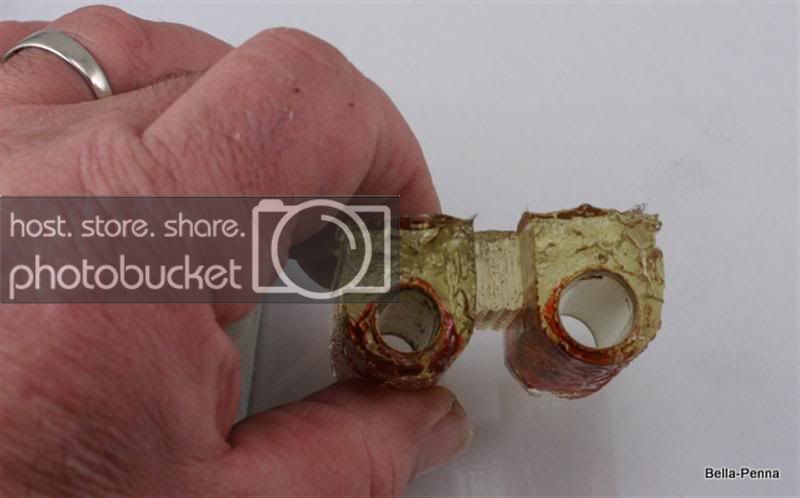

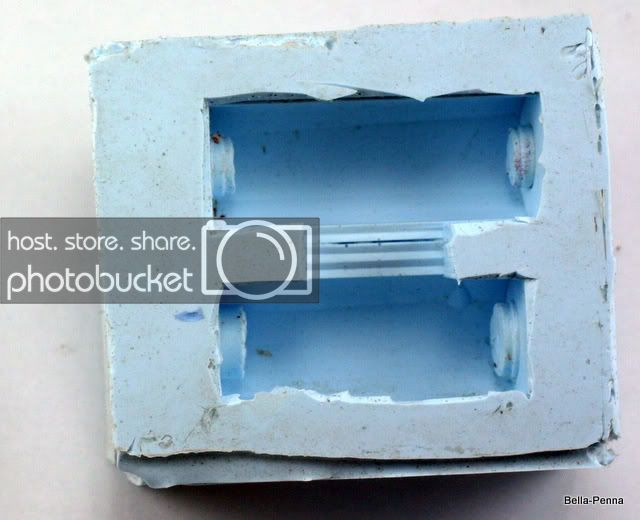

3rd removal of the finished casting and looking down the tubes:

Not a drop in the tubes and ain't that a good looking hand? Now for the finished casting made into a pen:

As everyone stepped backward one step I fell asleep and remained where I was so I received the mold a week or so ago and just now had a chance to test it.

This mold was a prototype and only held 2 tubes for one pen. It was not made for resale and was rough looking but functional.

I was skeptical that under pressure the built in stoppers would keep resin out of the tubes. I usually fill my tubes with clay and use corks glued to 1x1 thin strips of wood (cut up Paint stirrers). The mold eliminated the use of clay, corks and 1x1's and as a side benefit 50% or more PR.But would it work?

It's been a little cold the last few days so I heated the PR in my toaster oven to get it thin and pourable as water thinking that the thinner the pr the more chance that it would seep into the tubes under pressure.

Mixed my activator, poured and placed into the pot at 40PSI for 2 hrs. below are pictures of the final results. Not a drop of PR in the tubes.

Below are the results in pictures:

First the Mold:

Told you it's a prototype:wink:

Second, the pour:

Still not impressed?

3rd removal of the finished casting and looking down the tubes:

Not a drop in the tubes and ain't that a good looking hand? Now for the finished casting made into a pen: