AdventiveIowa

Member

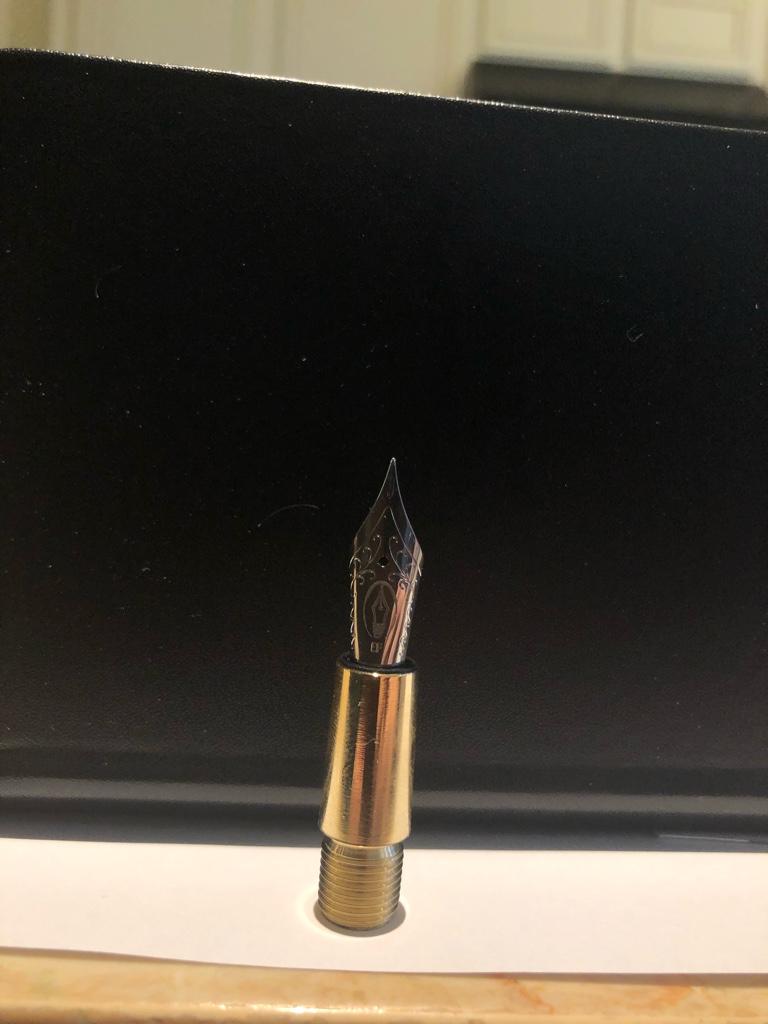

I finally finished the section for my Brass pen. It came out really well, and I've been starting to get the hang of turning again. It's been fun, I can't wait to make the body and cap to go with it.

I used an Edison #6 nib (AKA a Jowo #6, bought from Goulet Pens). I smoothed it out with some 0000 Steel Wool, and made it shine with a cleaning grease my Father-in-law showed me. Very happy with the results, not sure if I should've gone for a smoother finish though.

-Hank

Sent from my iPhone using Tapatalk

I used an Edison #6 nib (AKA a Jowo #6, bought from Goulet Pens). I smoothed it out with some 0000 Steel Wool, and made it shine with a cleaning grease my Father-in-law showed me. Very happy with the results, not sure if I should've gone for a smoother finish though.

-Hank

Sent from my iPhone using Tapatalk