jttheclockman

Member

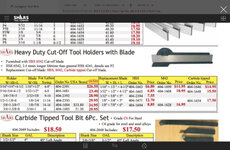

Does anyone know of a 1/16" carbide parting tool?? I know easy tools makes a 1/8" with replaceable blades. But I am looking for thinner because I do not want to waste alot of material and need to part off quite abit of rings. Standard HSS tools need to be sharpened after each cut more or less. If this is not possible does anyone know where I can get a 1/16" carbide blade to make my own. ( my only thought was to get some dado blades)

What do machinists use when parting thin stock with a metal lathe?? Could I adapt something to a wood lathe?? Thanks for the replys.

What do machinists use when parting thin stock with a metal lathe?? Could I adapt something to a wood lathe?? Thanks for the replys.