Chasboy1

Member

Hi folks, I purchased 2 lathe chisels from one of the recommended vendors here and I must say they are very well made.

My concern is what to expect that is 'normal' with a carbide tool vs. steel. (My old Shopsmith set is not HSS.). I have a square tip and round. I also realize that carbides use 'scraping' vs shearing cuts. As I use the square tool to round off the acrylic or acrylester blank, to matter how I try, I hear sounds that sound like chipouts. When I stop the machine I fortunately do not find chipouts, tho' the surface could be smoother. I have not used it on wood yet.

Is this normal?

I try to hold the tool at a slight angle and try to move along the length after some of the initial cuts, so I'm actually cutting with the side edge rather than the front. Is this ok?

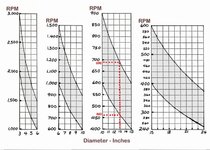

Another concern is turning speed. After watching many pen turning videos, it seems most turners use much faster speeds than I used to use when I was turning wood. Is this because of the acrylic materials? Does increased heat related friction help with cutting the acrylics?

Thanks folks. I'm not a rookie turner, but I like to know if I'm making a mistake somewhere.

My concern is what to expect that is 'normal' with a carbide tool vs. steel. (My old Shopsmith set is not HSS.). I have a square tip and round. I also realize that carbides use 'scraping' vs shearing cuts. As I use the square tool to round off the acrylic or acrylester blank, to matter how I try, I hear sounds that sound like chipouts. When I stop the machine I fortunately do not find chipouts, tho' the surface could be smoother. I have not used it on wood yet.

Is this normal?

I try to hold the tool at a slight angle and try to move along the length after some of the initial cuts, so I'm actually cutting with the side edge rather than the front. Is this ok?

Another concern is turning speed. After watching many pen turning videos, it seems most turners use much faster speeds than I used to use when I was turning wood. Is this because of the acrylic materials? Does increased heat related friction help with cutting the acrylics?

Thanks folks. I'm not a rookie turner, but I like to know if I'm making a mistake somewhere.