gtriever

Member

I've just completed a new dedicated table saw sled for pen blank cutting. It combines elements from my Picture Frame sled, Mini Crosscut sled, and from different web resources.

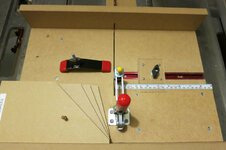

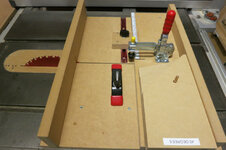

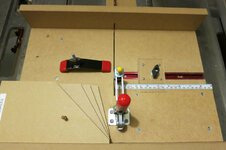

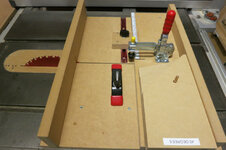

This sled is the same size as my mini crosscut sled; there is a stop block on the right side paired with a Starrett self-adhesive measuring tape for 90 degree cuts. The block has a piece of plexiglass screwed to the top, which extends over the Starrett rule for more precision. The block was installed in the t-slot and locked down, and then the edge was trimmed to match up with the sled's kerf. A vertical handle toggle clamp holds the work piece in place when cutting or trimming.

On the left side, a recessed tee nut is installed on the bottom of the sled. I shaved the head down on a 1/4-20 bolt and threaded it thru from the bottom, then secured it with blue Loctite. It's used for both a hold down clamp and also to mount angle templates for 15, 22.5, 30 and 45 degree cuts. The templates ride against the 3/4 flat fence and are also held in place under the hold down clamp. When they're not being used they store on top of the 3/4 flat fence and are held in place by a wooden dowel.

Hope you enjoy...

Art

This sled is the same size as my mini crosscut sled; there is a stop block on the right side paired with a Starrett self-adhesive measuring tape for 90 degree cuts. The block has a piece of plexiglass screwed to the top, which extends over the Starrett rule for more precision. The block was installed in the t-slot and locked down, and then the edge was trimmed to match up with the sled's kerf. A vertical handle toggle clamp holds the work piece in place when cutting or trimming.

On the left side, a recessed tee nut is installed on the bottom of the sled. I shaved the head down on a 1/4-20 bolt and threaded it thru from the bottom, then secured it with blue Loctite. It's used for both a hold down clamp and also to mount angle templates for 15, 22.5, 30 and 45 degree cuts. The templates ride against the 3/4 flat fence and are also held in place under the hold down clamp. When they're not being used they store on top of the 3/4 flat fence and are held in place by a wooden dowel.

Hope you enjoy...

Art