You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Does your CA do this? I think not....

- Thread starter edstreet

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

alphageek

Former Moderator

And what about the negatives that may be possible with that. You are relatively fixated on flexibility in every thread that you post in about CA recently. However, there could be a cost to that flexibility. There is at least 2 sides to every debate and product.

Many of us use CA (of a variety of different brands) because of its hardness. It offers a strong solid surface that is longer lasting than many other "typical" wood finishes, most of which are not designed for the day to day handling that pens get.

Add a bunch of flex agents into CA and you might not get the durable finish that you did in the past. Just because you can twist a product in knots doesn't mean it will make a great pen finish.

Many of us use CA (of a variety of different brands) because of its hardness. It offers a strong solid surface that is longer lasting than many other "typical" wood finishes, most of which are not designed for the day to day handling that pens get.

Add a bunch of flex agents into CA and you might not get the durable finish that you did in the past. Just because you can twist a product in knots doesn't mean it will make a great pen finish.

thewishman

Member

That should be great for gluing tubes in.

I think the use of the flexible CA would be more as a glue than a hard finish Dean. The major weakness of CA glue is that it lacks shear strength - it has great pull strength (remember the commercials showing it picking up a car with one drop of CA) but push it sideways and it is next to nothing. The glue shown in the utube would hold better in the sheer directions which is better for gluing in tubes than typical CA,And what about the negatives that may be possible with that. You are relatively fixated on flexibility in every thread that you post in about CA recently. However, there could be a cost to that flexibility. There is at least 2 sides to every debate and product.

Many of us use CA (of a variety of different brands) because of its hardness. It offers a strong solid surface that is longer lasting than many other "typical" wood finishes, most of which are not designed for the day to day handling that pens get.

Add a bunch of flex agents into CA and you might not get the durable finish that you did in the past. Just because you can twist a product in knots doesn't mean it will make a great pen finish.

PR_Princess

Member

That should be great for gluing tubes in.

Loctite 4902/4903 were initially formulated for medical devices.

These glues are available for purchase, and will run you about $65.00 for a 20g bottle (less than 3/4 of an oz)....But only $504.00 you buy it in one pound bottles.

For me, I think I'll "stick" with regular CA or epoxy.

Henkel Loctite 4902 Flexible Cyanoacrylate Adhesive Clear 20 g Bottle

Loctite - 1875841 - 4902™ Instant Adhesive, 20 gram Bottle

Loctite 4902 Flexible Cyanoacrylate Adhesive - Clear Liquid 1 Pound Bottle - Shear Strength 1745 psi, Tensile Strength 2085 psi -1875842 [PRICE is per BOTTLE] - - Amazon.com

Henkel Loctite 4903 Flexible Cyanoacrylate Adhesive Clear 20 g Bottle

If that Loc-tite product can provide all of the qualities that are associated with a workable, durable,high-gloss etc finish; wouldn't it be desirable assuming it was affordable and posed no health and safety risks? I am not making a statement; I asking all a genuine question.

If the answer is yes, I would try it. Then only time and handling will tell. I am on the right track?

If the answer is yes, I would try it. Then only time and handling will tell. I am on the right track?

OKLAHOMAN

Member

While I agree flexibility in a CA finish and tube adhesion could be beneficial I think and I will stand corrected if wrong Ed was just showing CA flexibility to the extreme and not recommending we buy Loctite 4902 or 4903. Their are a number of CA's that have some flex that are not made for the medical industry at prices that are more in line with what we as pen makers are used to paying maybe a few dollars more but not in the same ball park as Loctite 4902 and 4903.

edstreet

Member

While I agree flexibility in a CA finish and tube adhesion could be beneficial I think and I will stand corrected if wrong Ed was just showing CA flexibility to the extreme and not recommending we buy Loctite 4902 or 4903. Their are a number of CA's that have some flex that are not made for the medical industry at prices that are more in line with what we as pen makers are used to paying maybe a few dollars more but not in the same ball park as Loctite 4902 and 4903.

Interesting to note was that Roy was the only one who seemed to understand the purpose of posting the video

If that Loc-tite product can provide all of the qualities that are associated with a workable, durable,high-gloss etc finish; wouldn't it be desirable assuming it was affordable and posed no health and safety risks? I am not making a statement; I asking all a genuine question.

If the answer is yes, I would try it. Then only time and handling will tell. I am on the right track?

I have to commend you. You have an open mind and willing to look for better ways of doing things and that is what is at stake here. By limiting yourself to certain things only you are doing more harm than good, which you are obviously not doing.

As for the whole flex thing. Those whom I have shown, in person mind you, a few samples of what flex can do for you really understands things. As to the crowd who seems to be bashing on flex, I just feel bad for them as they have yet to reach enlightenment, that comes with education among other things.

ed4copies

Local Chapter Manager

As for the whole flex thing. Those whom I have shown, in person mind you, a few samples of what flex can do for you really understands things. As to the crowd who seems to be bashing on flex, I just feel bad for them as they have yet to reach enlightenment, that comes with education among other things.

Certainly no lack of self-esteem!

"I'm so good, too bad about you all!!"

Certainly no lack of self-esteem!

"I'm so good, too bad about you all!!"

edstreet

Member

That should be great for gluing tubes in.

Not really, see what Roy posted. He was spot on in his comments.

alphageek

Former Moderator

Those whom I have shown, in person mind you, a few samples of what flex can do for you really understands things. As to the crowd who seems to be bashing on flex, I just feel bad for them as they have yet to reach enlightenment, that comes with education among other things.

Ed, I don't see a crowd bashing on flex. All I've seen is that every chance you get, you tell us how bad certain products are to use no matter how some others on the forum have had great results with those products. If you want us to reach enlightenment, then you'll have to share the great examples wi us rather than just bashing the rest. As for being open minded, I suggest yo do the same. CA îs one of the most varied things in pen turning. There is dozens of methods and products, which means the variations are in the hundreds not even counting for each persons take on it.

For example, I've mostly stayed out of the acetone/non-acetone discussion because I don't use accelator when I finish.... However, I do see beautiful pens that others have made using both, so it can't be all bad, no matter how often you tell us that acetone is as bad for a finish.

Why does it matter if others express their "approval" or "disapproval" of how something is done? If the delivery or content of a comment causes one to believe they are stupid or inexperienced and I therefore irrationally adopted that belief (that I believe I am stupid, etc.) wouldn't I have the problem? All questions were asked rhetorically LOL.

Why information is shared or even how it is shared, I don't believe detracts from the value of the information. This isn't about who we are going to include in our wills or share dinner with. We are making pens...and 90% of the time building relatively friendly, at least cordial relationships. I think those are pretty good odds.

Okay...I said what I thought , in this great country that we live in, in the hopes of peace, not perfection, just peace.

, in this great country that we live in, in the hopes of peace, not perfection, just peace.

Now, I am going to read The Ultimate Pen Book that my beautiful sister in law sent me (Copyright 2010). She found it in the her public library for 10 bucks!

Have a great night folks .

.

Why information is shared or even how it is shared, I don't believe detracts from the value of the information. This isn't about who we are going to include in our wills or share dinner with. We are making pens...and 90% of the time building relatively friendly, at least cordial relationships. I think those are pretty good odds.

Okay...I said what I thought

Now, I am going to read The Ultimate Pen Book that my beautiful sister in law sent me (Copyright 2010). She found it in the her public library for 10 bucks!

Have a great night folks

OKLAHOMAN

Member

Don't take the bate

Are you saying I was wrong in my assessment that it would be more beneficial as a glue that a finishing product? Interesting. Do you ccconsider that bashing?

Last edited:

OKLAHOMAN

Member

Well said!

Why does it matter if others express their "approval" or "disapproval" of how something is done? If the delivery or content of a comment causes one to believe they are stupid or inexperienced and I therefore irrationally adopted that belief (that I believe I am stupid, etc.) wouldn't I have the problem? All questions were asked rhetorically LOL.

Why information is shared or even how it is shared, I don't believe detracts from the value of the information. This isn't about who we are going to include in our wills or share dinner with. We are making pens...and 90% of the time building relatively friendly, at least cordial relationships. I think those are pretty good odds.

Okay...I said what I thought, in this great country that we live in, in the hopes of peace, not perfection, just peace.

Now, I am going to read The Ultimate Pen Book that my beautiful sister in law sent me (Copyright 2010). She found it in the her public library for 10 bucks!

Have a great night folks.

OKLAHOMAN

Member

Tony that was directed at Ed S. Tiring to stop a thread from going down hill

:biggrin:

:biggrin:

bait? LOL. Hey...made one of your RBs yesterday. I need to post pics. I have a light tent, but too darn lazy.

jeremiahhix

Member

I have switched to a flex CA finish in the past 8 or so months and ti be honest I am seeing better results out of my pens. I have a lot of attorneys that travel around the country every week that I work with and I have sent pens with several of them to see how the humidity factor against wood held up. As we all know when wood goes from dry to humid back to dry ect... it moves. It expands and contracts. This being said if you dipped a piece of wood in glass and it expanded what would happen to the glass? If you did the same with something that has flex what would happen then? I had a couple pens (this is about 5-8 months after traveling) come back to me cracked which had (not naming the brand because frankly this is simply passing information along, not trying to start a brand war)a rigid CA finish on them. So far I have 6 pens (flex CA) out that are traveling the country and have been for the past 7-8 months that haven't come back to me. So far so good, time obviously will tell. This is in no way saying one is better than the other, it is simple facts that I have seen to be true. Different strokes for different folks as they say. The tests I have going are simply to see which ones work the best in my opinion. For now I will continue to go with a Flex CA. To each their own.

OKLAHOMAN

Member

Jeremiah, thanks as you said wood expands and contracts and back in my days when I was doing art shows across the country that was the biggest reason I never did wood pens. Going from Houston with humidity in the 90's to Phoenix where it never hit the teens you could hear them crack. I might have tried a flex CA if I had been educated about them.

Dan Masshardt

Member

I have switched to a flex CA finish in the past 8 or so months and ti be honest I am seeing better results out of my pens. I have a lot of attorneys that travel around the country every week that I work with and I have sent pens with several of them to see how the humidity factor against wood held up. As we all know when wood goes from dry to humid back to dry ect... it moves. It expands and contracts. This being said if you dipped a piece of wood in glass and it expanded what would happen to the glass? If you did the same with something that has flex what would happen then? I had a couple pens (this is about 5-8 months after traveling) come back to me cracked which had (not naming the brand because frankly this is simply passing information along, not trying to start a brand war)a rigid CA finish on them. So far I have 6 pens (flex CA) out that are traveling the country and have been for the past 7-8 months that haven't come back to me. So far so good, time obviously will tell. This is in no way saying one is better than the other, it is simple facts that I have seen to be true. Different strokes for different folks as they say. The tests I have going are simply to see which ones work the best in my opinion. For now I will continue to go with a Flex CA. To each their own.

How does the flex finish feel? Can you tell the finishes apart once done by visual or feel?

No argument that there would be an advantage to a flexible finish over one that is rigid if you want the glass like finish. The question I would ask (because I don't know the answer) is -- do you get as, for want of a better word, 'nice' a glassy finish with the flex?

edstreet

Member

I have switched to a flex CA finish in the past 8 or so months and ti be honest I am seeing better results out of my pens. I have a lot of attorneys that travel around the country every week that I work with and I have sent pens with several of them to see how the humidity factor against wood held up. As we all know when wood goes from dry to humid back to dry ect... it moves. It expands and contracts. This being said if you dipped a piece of wood in glass and it expanded what would happen to the glass? If you did the same with something that has flex what would happen then? I had a couple pens (this is about 5-8 months after traveling) come back to me cracked which had (not naming the brand because frankly this is simply passing information along, not trying to start a brand war)a rigid CA finish on them. So far I have 6 pens (flex CA) out that are traveling the country and have been for the past 7-8 months that haven't come back to me. So far so good, time obviously will tell. This is in no way saying one is better than the other, it is simple facts that I have seen to be true. Different strokes for different folks as they say. The tests I have going are simply to see which ones work the best in my opinion. For now I will continue to go with a Flex CA. To each their own.

How does the flex finish feel? Can you tell the finishes apart once done by visual or feel?

The flex finish feels like any other CA finish does.

In some cases (i.e. the glue that I use) you have the BLO+CA effect in the bottle so no need to add that. (no yellowing over time either)

The additive that yields 'flex' is a rubber byproduct, it's clear and provides added strength for bonding. Adds to shock resistant and bend and forms with pressure.

I.e. In person I can show you a pen that has been finished with a flex CA and a clip that has caused the CA to MOVE and reduce stress, pressure and tension from the clip. Also you can put one in a chuck and the CA finish will *NOT* crack or spiderweb. Yet it will mold and bend to the stress provided. (to a limited degree mind you)

In closing, no you can not tell the difference with casual observation.

jeremiahhix

Member

No argument that there would be an advantage to a flexible finish over one that is rigid if you want the glass like finish. The question I would ask (because I don't know the answer) is -- do you get as, for want of a better word, 'nice' a glassy finish with the flex?

It's not too difficult to get a glass finish out of the flex Ca. The term flex is slightly misunderstood by a lot of people (it was to me until I tried it) that haven't tried it yet. I finishes hard like rigid Ca for the most part. Here is a picture of the first pen I made with a flex Ca finish. It has 5 or 6 coats over my wastewood casting. Please excuse the lack of quality, this was taken with a cell phone a little under a year ago.

alphageek

Former Moderator

The flex finish feels like any other CA finish does. In some cases (i.e. the glue that I use) you have the BLO+CA effect in the bottle so no need to add that. (no yellowing over time either) The additive that yields 'flex' is a rubber byproduct, it's clear and provides added strength for bonding. Adds to shock resistant and bend and forms with pressure. I.e. In person I can show you a pen that has been finished with a flex CA and a clip that has caused the CA to MOVE and reduce stress, pressure and tension from the clip. Also you can put one in a chuck and the CA finish will *NOT* crack or spiderweb. Yet it will mold and bend to the stress provided. (to a limited degree mind you) In closing, no you can not tell the difference with casual observation.

So if this is truly the case, I have one question for you. Instead of constantly bashing other bands and beating around the bush, why haven't you just shared the details of the brand, model and source of this amazing product? Most of us when asked what products work for us, we share our sources. You seem to want to keep this a secret and instead just bash the rest.

alphageek

Former Moderator

It's not too difficult to get a glass finish out of the flex Ca. The term flex is slightly misunderstood by a lot of people (it was to me until I tried it) that haven't tried it yet. I finishes hard like rigid Ca for the most part. Here is a picture of the first pen I made with a flex Ca finish. It has 5 or 6 coats over my wastewood casting. Please excuse the lack of quality, this was taken with a cell phone a little under a year ago.

Beautiful pen!! It would be great if you posted more!! So... Since your promoting the finish, would you share more details? What CA, do you use accelator, etc?

OKLAHOMAN

Member

Dean I also have a question as I have read every post in this thread and the only bashing is coming from you. I see no bashing of any brand. If a brand was bashed in an other thread your comments belong there. This thread has all been a nice talk except for your and Ed Browns comments. Can't we all play nice

jeremiahhix

Member

Personally I use Bob Smith Industries Super Gold+ Medium. I found if you sand smooth (typically with #600 then with #800 Abranet followed with #2400 or so auto sandpaper (wet) then polished with Novus #3 and #2 it is extremely easy to get the glass looking finish. That is my method, happy to share because we all want to better the industry and help each other out.

Here is a link to the CA I use:http://www.amazon.com/Super-gold-ga...F8&qid=1435464829&sr=1-1&keywords=super-gold+

Here is a link to the CA I use:http://www.amazon.com/Super-gold-ga...F8&qid=1435464829&sr=1-1&keywords=super-gold+

OKLAHOMAN

Member

[thank you. We are here to learn, maybe we all might not agree with any method but we need to have an open mindQUOTE=jeremiahhix;1778141]Personally I use Bob Smith Industries Super Gold+ Medium. I found if you sand smooth (typically with #600 then with #800 Abranet followed with #2400 or so auto sandpaper (wet) then polished with Novus #3 and #2 it is extremely easy to get the glass looking finish. That is my method, happy to share because we all want to better the industry and help each other out.

Here is a link to the CA I use:Amazon.com : Super-gold gap filling 2oz Bob Smith Ind. : General Purpose Glues : Office Products[/QUOTE]

Here is a link to the CA I use:Amazon.com : Super-gold gap filling 2oz Bob Smith Ind. : General Purpose Glues : Office Products[/QUOTE]

jeremiahhix

Member

And this is the accellerator I use: http://www.amazon.com/Bob-Smith-151...sim_229_1?ie=UTF8&refRID=1HMCTJSGPQ7GDYFJEF30

The Ca is pricey, honestly I find it to be worth it because of the quality of finish it provides. Everyone I have showed it to in person has switched to it, no questions asked. If someone hasn't tried it I challenge you to give it a try. What's the worst that can happen? You find out you dont like it and you have some great medical grade super glue to seal up wounds with for the family... I have closed up several scrapes with it. It doesn't sting like other glues or even the liquid skin stuff. It doesn't melt styrofoam either. It is a much less abrasive glue. Great stuff!

The Ca is pricey, honestly I find it to be worth it because of the quality of finish it provides. Everyone I have showed it to in person has switched to it, no questions asked. If someone hasn't tried it I challenge you to give it a try. What's the worst that can happen? You find out you dont like it and you have some great medical grade super glue to seal up wounds with for the family... I have closed up several scrapes with it. It doesn't sting like other glues or even the liquid skin stuff. It doesn't melt styrofoam either. It is a much less abrasive glue. Great stuff!

jeremiahhix

Member

Most turners use Micromesh, I have some and I use it occasionally but the sandpapers I listed above will give a nice glass finish on my pens.

If we all did the same thing everyday this world would be a boring place. Variety brings a flavor and spice to life. An open mind will allow us to better ourselves. You are right Roy.

If we all did the same thing everyday this world would be a boring place. Variety brings a flavor and spice to life. An open mind will allow us to better ourselves. You are right Roy.

Dale Lynch

Member

edstreet

Member

The flex finish feels like any other CA finish does. In some cases (i.e. the glue that I use) you have the BLO+CA effect in the bottle so no need to add that. (no yellowing over time either) The additive that yields 'flex' is a rubber byproduct, it's clear and provides added strength for bonding. Adds to shock resistant and bend and forms with pressure. I.e. In person I can show you a pen that has been finished with a flex CA and a clip that has caused the CA to MOVE and reduce stress, pressure and tension from the clip. Also you can put one in a chuck and the CA finish will *NOT* crack or spiderweb. Yet it will mold and bend to the stress provided. (to a limited degree mind you) In closing, no you can not tell the difference with casual observation.

So if this is truly the case, I have one question for you. Instead of constantly bashing other bands and beating around the bush, why haven't you just shared the details of the brand, model and source of this amazing product? Most of us when asked what products work for us, we share our sources. You seem to want to keep this a secret and instead just bash the rest.

Note the accelerator is not acetone based. It also provides more support in the lifespan of the pen.

Also worth noting is something I would urge everyone to look into is ... CA hinges. It's not a hard concept to understand but it does work very good in our industry. I have been using a flex CA in every photo I have posted here on IAP for a good number of years now. Do I share info? Yes I do, it's mostly to those who ask me directly.

It's also not my job to beat everyone over the head with something and force feed education to the masses, yet I am being ask to do just that. What I will do is this, I will put info out there and those who are interested, eager and willing to see things will be very pleased with the results. Going against the group think mentality and looking for superior technology is what we should be about no?

Numerous people here will report they use flex agents in their CA with beautiful results. Many may not understand or comprehend the long term helpful effects of this and that's fine.

Dale Lynch

Member

Flex ca is great for a finish but there are limitations in blanks building.I will take a pic tomorrow of the same pen to show.

alphageek

Former Moderator

Personally I use Bob Smith Industries Super Gold+ Medium. I found if you sand smooth (typically with #600 then with #800 Abranet followed with #2400 or so auto sandpaper (wet) then polished with Novus #3 and #2 it is extremely easy to get the glass looking finish. That is my method, happy to share because we all want to better the industry and help each other out. Here is a link to the CA I use:http://www.amazon.com/Super-gold-gap-filling-Smith-Ind/dp/B0000DD1QN/ref=sr_1_1?s=office-products&ie=UTF8&qid=1435464829&sr=1-1&keywords=super-gold%2B

Awesome!!! Thank you VERY much... This kind of direct answer is very helpful! From an education perspective, can you tell me how we know this has "flex" agents? It's gap filling, but I don't know that anyone has ever pointed out a correlation there.... Or is it something else I'm missing?

alphageek

Former Moderator

Dean I also have a question as I have read every post in this thread and the only bashing is coming from you. I see no bashing of any brand. If a brand was bashed in an other thread your comments belong there. This thread has all been a nice talk except for your and Ed Browns comments. Can't we all play nice

I see no bashing from me. If you see bashing, I welcome you to point it out to the moderators. What I was trying to do is further the discussion with some questions, but I think I'lll stop asking Ed since my last one was a pretty straight forward question - Ed obviously doesn't want to share the answer so I'm glad others are!

edstreet

Member

Personally I use Bob Smith Industries Super Gold+ Medium. I found if you sand smooth (typically with #600 then with #800 Abranet followed with #2400 or so auto sandpaper (wet) then polished with Novus #3 and #2 it is extremely easy to get the glass looking finish. That is my method, happy to share because we all want to better the industry and help each other out. Here is a link to the CA I use:Amazon.com : Super-gold gap filling 2oz Bob Smith Ind. : General Purpose Glues : Office Products

Awesome!!! Thank you VERY much... This kind of direct answer is very helpful! From an education perspective, can you tell me how we know this has "flex" agents? It's gap filling, but I don't know that anyone has ever pointed out a correlation there.... Or is it something else I'm missing?

Correct, you are missing something.

Note the part about the CA hinges?

I have been testing things out for some time now...

Attachments

edstreet

Member

So if this is truly the case, I have one question for you. Instead of constantly bashing other bands and beating around the bush, why haven't you just shared the details of the brand, model and source of this amazing product? Most of us when asked what products work for us, we share our sources. You seem to want to keep this a secret and instead just bash the rest.

The answer is simple.

Because it's not just one product ....

Hence the purpose of this post in the start.

alphageek

Former Moderator

Correct, you are missing something. Note the part about the CA hinges? I have been testing things out for some time now...

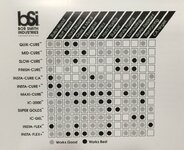

Thank you Ed, I think you just round about answered my other question to you. However your answer doesn't help my question to Jeremieh, it makes it worse. You point out the part about CA hinges, but that points to their insta-flex line. Jeremieh says he uses the super gold, which doesn't line up in your chart with the flex stuff. So my question remains... If the supergold is being used as a great example of flex CA, how do we figure that out since it's not listed as a flex?

Jeremieh - I'm not doubting your results, just trying to figure out how to know its a "flex" product.

OKLAHOMAN

Member

Dean, I'm not sure and I could be wrong but the chart shows the Supergold best for rubber and good for hinge. I would guess that's a flex CA

Signed-In Members Don't See This Ad

edstreet

Member

Correct, you are missing something. Note the part about the CA hinges? I have been testing things out for some time now...

Thank you Ed, I think you just round about answered my other question to you. However your answer doesn't help my question to Jeremieh, it makes it worse. You point out the part about CA hinges, but that points to their insta-flex line. Jeremieh says he uses the super gold, which doesn't line up in your chart with the flex stuff. So my question remains... If the supergold is being used as a great example of flex CA, how do we figure that out since it's not listed as a flex?

Jeremieh - I'm not doubting your results, just trying to figure out how to know its a "flex" product.

It is listed as a flex. Super gold is odorless because it is methoxyethyl. Look at it as insta-flex with additional stuff in it. Super-gold is the flagship product. Nor is it cheap bu I can show you, in person, the benefits of it's use.

I know it's a flex because of 2 reasons. A) I have used it and verified it myself and B) I called and spoke numerous times with the company about their products. Also with their help and locktite's help I have a good write up on several topics: Shattered glass effect, accelerators, CA cure process, etc.. Also if you look on their gallery page guess who's work you will find there under the 'art' section. BSI Adhesive's Photo Gallery

Now let me ask YOU a question. If you had several game changers and you knew beyond any doubt that any topic relating to CA would go bad to horrible due to a number of reasons and you knew that most people would not be able to wrap their heads about the new stuff; how reluctant would you be to share info? I would like to point out the start of this thread as a very good example of this, look at the number of people who ganked and derailed the thread topic at hand.