BSea

Member

At our recent local IAP meeting, I did a demo on doing a custom finial & centerband for a Jr Gent I with a closed end barrel all from one 5 1/4" blank.

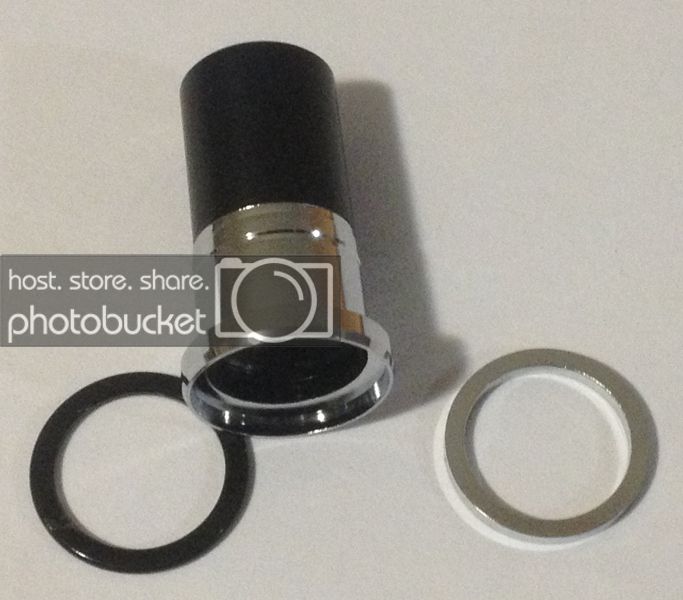

Here's the ring.

These are a bit smaller than they look. Here's the same ring on a penny.

And this ring was an oops ring because it's actually too big. That's the problem with doing demos on someone else's lathe. I didn't have the tailstock set right when I drilled, and the hole was too large.:redface: So I didn't get the entire pen from 1 blank. I had to use a scape for the centerband when I got home.:frown:

Here's the pen.

Here's the ring.

These are a bit smaller than they look. Here's the same ring on a penny.

And this ring was an oops ring because it's actually too big. That's the problem with doing demos on someone else's lathe. I didn't have the tailstock set right when I drilled, and the hole was too large.:redface: So I didn't get the entire pen from 1 blank. I had to use a scape for the centerband when I got home.:frown:

Here's the pen.