Exabian

Member

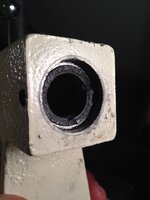

Can any one explain why or how this happened? I was drilling on the lathe and as I turned the hand wheel it snapped off in my hand. Luckily the company is sending me a new hand wheel free of charge, but I would like to ensure this doesn't happen in the future. So has this happened to anyone else or does any one have an idea that might have caused it.

My lathe is a shop fox 1704.

thanks.

My lathe is a shop fox 1704.

thanks.