This is a question that has puzzled me since I saw the first tailstock DRO here. Don't get me wrong, I think they 'can' be useful, but I was wondering if most people are actually getting better results than simply doing it the old way by making a mark in the drill bit?

What point are you using as the Zero reference?

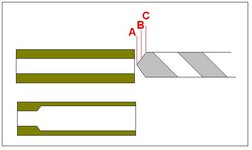

Please look at the sketch. You can see that if you wanted to drill a hole to a certain depth, then the zero point is important.

If you choose A or C, then at what point do you zero the DRO?

If you choose B ( edge of existing hole ) then surely the difference between the existing pilot hole and the finished size would alter the depth.

The other thing that I wondered about is that most DRO's on calipers that I've seen, automatically switch off after a few minutes to save the battery. What do you do if it switches off, half way through your drilling.

Like I said, I think they 'can' be useful. I just wonder how most people are using them. :biggrin:

What point are you using as the Zero reference?

Please look at the sketch. You can see that if you wanted to drill a hole to a certain depth, then the zero point is important.

If you choose A or C, then at what point do you zero the DRO?

If you choose B ( edge of existing hole ) then surely the difference between the existing pilot hole and the finished size would alter the depth.

The other thing that I wondered about is that most DRO's on calipers that I've seen, automatically switch off after a few minutes to save the battery. What do you do if it switches off, half way through your drilling.

Like I said, I think they 'can' be useful. I just wonder how most people are using them. :biggrin: