SteveJ

Member

I have been working on a new design and am not sure it is worth assembling into a pen.

It was a fairly complicated build. First I created the block, which consisted of white, black, white veneer sandwiched between mahogany and wenge.

Then I cut triangles from that:

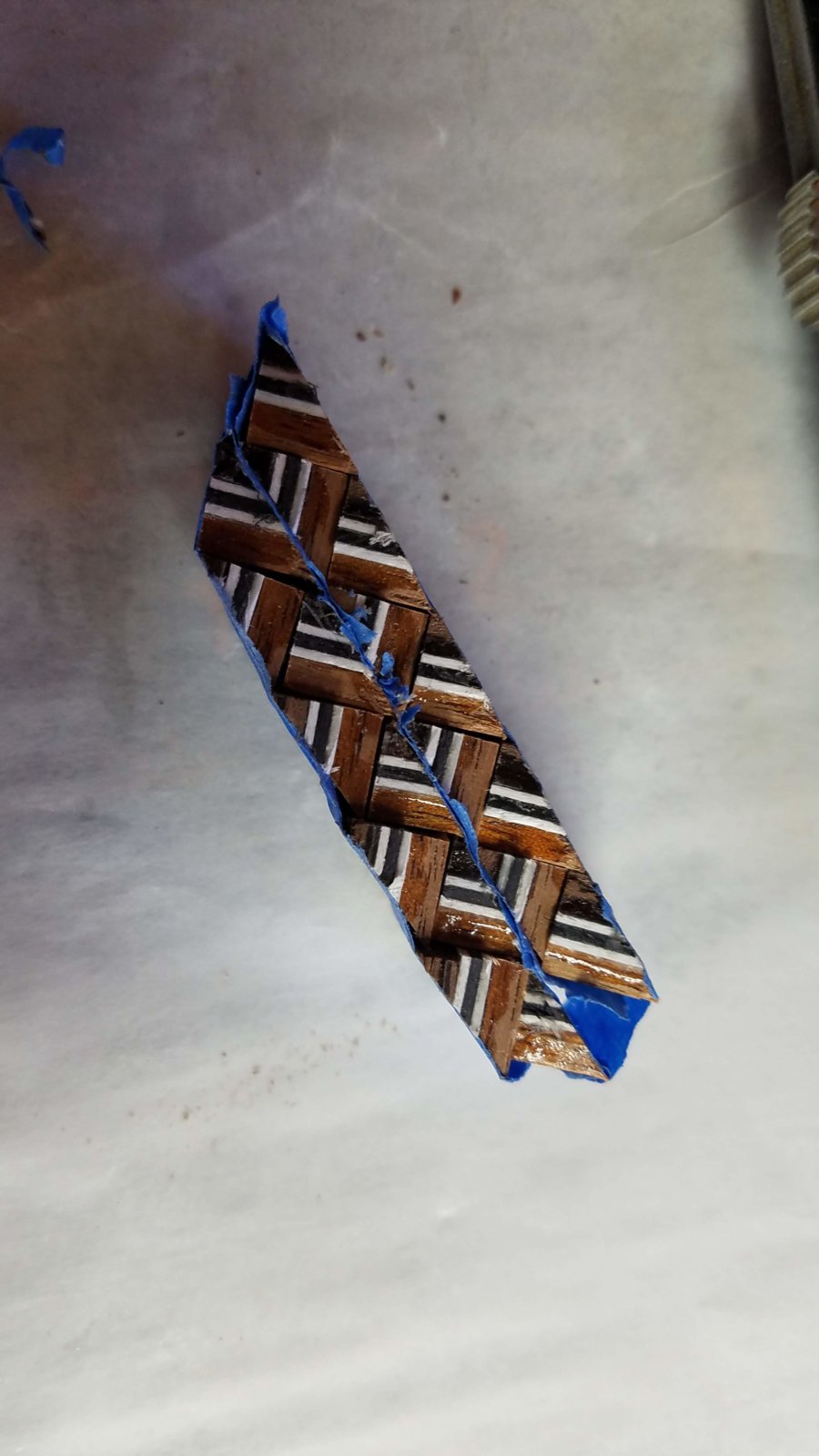

I glued those together to create a blank which looked like this (Taped together here)

From there I put white veneer around it and more mahogany (not shown) to produce this. (The beginning of another blank is also shown using the same triangles)

So, the problem with the first one is that the triangles are not even and in my opinion they don't look good. For the "zigzag" blank I have tried to make sure each triangle is the exact same size. Anyway, after all that, would you put the original blank on a kit or just toss it? As difficult as this blank was to make, I am not sure I would repeat it unless there is significant encouragement here for me to try it again!

It was a fairly complicated build. First I created the block, which consisted of white, black, white veneer sandwiched between mahogany and wenge.

Then I cut triangles from that:

I glued those together to create a blank which looked like this (Taped together here)

From there I put white veneer around it and more mahogany (not shown) to produce this. (The beginning of another blank is also shown using the same triangles)

So, the problem with the first one is that the triangles are not even and in my opinion they don't look good. For the "zigzag" blank I have tried to make sure each triangle is the exact same size. Anyway, after all that, would you put the original blank on a kit or just toss it? As difficult as this blank was to make, I am not sure I would repeat it unless there is significant encouragement here for me to try it again!