TXPhi67

Member

How about a Sherline 4000 lathe? Hehehehehe

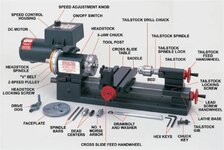

Just got the lathe today and have my work cut out for me. It needs some TLC and is missing a good portion of the parts.

The bed is mounted on a solid mount and has two plexiglass protective covers on it. Motor and Headstock look to be in good condition and it looks like it may have an automatic feed.

But, its missing pretty much everything else. I've looked on eBay and see some of the items I think I need. But this is my first metal lathe of any kind. So, if any of you with the experience feel so inclined - I would love all the advice you are willing to give.

My goal is to use it to turn some items specifically for pen turning. This includes bushings as well as possibly some pen parts. I have a few other plans for its use kicking around in my head, but I need to start somewhere.

I downloaded and just finished printing what is labeled as the lathe user manual and will be going over it shortly as well.

But beyond that - not sure what exactly to do after cleaning the lathe.

Any suggestions where I can find parts (used is just fine), instructions, suggestions, etc?

Take care all,

Just got the lathe today and have my work cut out for me. It needs some TLC and is missing a good portion of the parts.

The bed is mounted on a solid mount and has two plexiglass protective covers on it. Motor and Headstock look to be in good condition and it looks like it may have an automatic feed.

But, its missing pretty much everything else. I've looked on eBay and see some of the items I think I need. But this is my first metal lathe of any kind. So, if any of you with the experience feel so inclined - I would love all the advice you are willing to give.

My goal is to use it to turn some items specifically for pen turning. This includes bushings as well as possibly some pen parts. I have a few other plans for its use kicking around in my head, but I need to start somewhere.

I downloaded and just finished printing what is labeled as the lathe user manual and will be going over it shortly as well.

But beyond that - not sure what exactly to do after cleaning the lathe.

Any suggestions where I can find parts (used is just fine), instructions, suggestions, etc?

Take care all,