W.Y.

Member

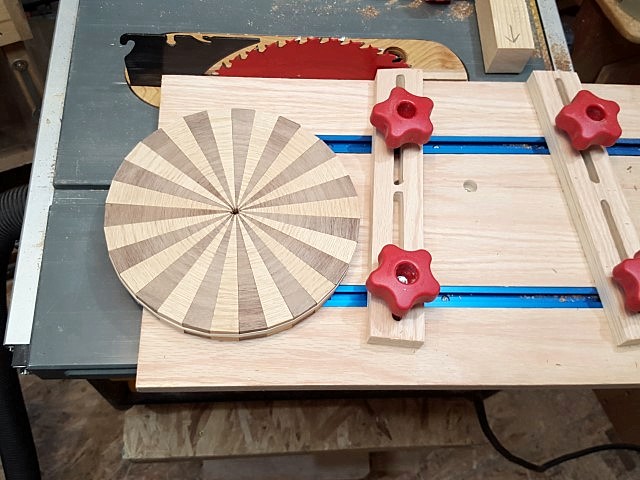

Made a new and improved Wedgie Sled yesterday compared to my previous one for cutting segments to make segmented bowls .

Well , Of course I had to try it out

I used my 18 segment wedge and cut a 3.5" wide strip of the same plywood that I made the sled with . That is a 7" round board as shown but if I decide to use it rather than just toss it out as a test piece and "turn" it into a bowl , I will probably cut 16 very thin strips of contrasting wood to put between each segment which will probably increase the diameter to over 8 inches . .

As far as the accuracy goes right off the saw , it just doesn't get much better than this . It just has an elastic band holding it together at this point .

Well , Of course I had to try it out

I used my 18 segment wedge and cut a 3.5" wide strip of the same plywood that I made the sled with . That is a 7" round board as shown but if I decide to use it rather than just toss it out as a test piece and "turn" it into a bowl , I will probably cut 16 very thin strips of contrasting wood to put between each segment which will probably increase the diameter to over 8 inches . .

As far as the accuracy goes right off the saw , it just doesn't get much better than this . It just has an elastic band holding it together at this point .