mkemmet

Member

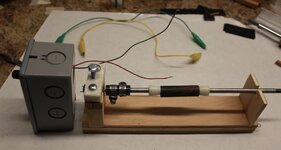

For Christmas I received a PSI slow-speed blank drying system from my daughter. Up to now I've used a fast-drying finishes like Mylands or Aussie Oil. Not wanting to disappoint her, I want to show her when she comes home in two weeks how I've put it to use and teach her to use it as well. Any advice will be greatly appreciated. I looked for a YouTube video but was unable to find anything relevant. Thanks!